Choosing the Best Wire Stripping Machine: A Guide for Scrappers & Electricians

Whether you’re recycling scrap wire for profit or stripping cables for installation work, choosing the right wire stripping machine can make or break your operation. The right tool speeds up processing, improves copper recovery, reduces injury risk, and ensures compliance with environmental regulations.

This guide breaks down the key factors to help you select the right model based on volume, wire type, and budget.

- Manual vs. Automatic: What Type Do You Need?

Wire strippers fall into two categories:

- Manual Wire Strippers — Budget-friendly and suitable for hobbyists or low-volume users.

- Automatic Wire Strippers — Powered by drill or motor, these are ideal for higher volumes and offer faster, safer results.

If you’re processing more than 50 lbs of wire monthly, an automatic model will save time and pay for itself quickly.

- Wire Compatibility: Size and Type

Look for a stripper that supports:

- Your required cable diameter range (e.g., 18 AWG up to 3 1/4″)

- Multiple wire types: THHN, Romex, stranded, multi-conductor, solid core

StripMeister’s E350X, for example strips up to 1 “which covers nearly all common wires, perfect for any tradesmen.

- Precision is Profit: Blade Depth Matters

Avoid poorly built machines. Precision and rigidity are the key to reliable and streamlined wire stripping machines with :

- Precise and Smooth blade depth Adjustment

- Rigid and Easy to Adjust Wire guides

- Hardened steel blades and Feed Wheels.

These features ensure clean cuts and better-grade scrap.

- Don’t Skimp on Safety & Maintenance

Manual stripping tools can cause injuries and fatigue. A well-made machine helps reduce:

- Cut and strain risks

- Downtime from clogs or worn parts

StripMeister machines are made from aluminum with few moving parts, minimizing maintenance and extending lifespan.

- Return on Investment (ROI): How Fast Will It Pay Off?

Ask yourself:

- How much copper do I process per month?

- What’s my current scrap value vs. potential value with clean cuts?

- How much time or labor could I save?

In many cases, the machine pays for itself in just weeks—especially when upgrading from manual tools.

Spotlight: The StripMeister™ Original

For hobbyists, electricians, or first-time scrappers, the StripMeister™ Original offers unbeatable value. It handles:

- Wire sizes from #18 to 250 MCM

- Diameters from 100″ to 0.79″

- Common types like Romex, braided, and stranded wire

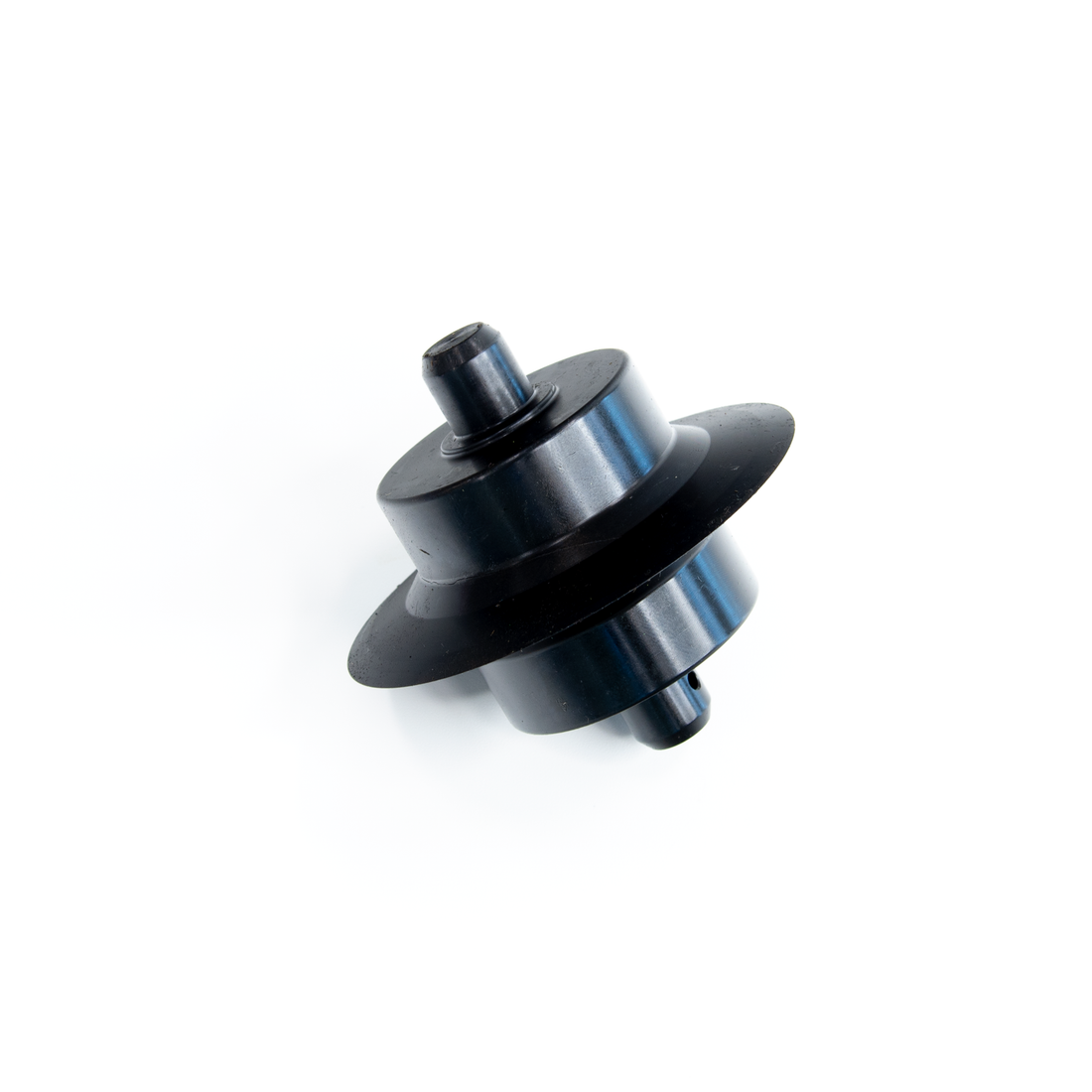

Made with aircraft-grade aluminum and along with hardened tool steel knife and feed wheel, this compact unit includes a blade depth reference indicator for precision and ease of use.

StripMeister Lineup at a Glance

- Original – Drill-powered, entry-level favorite

- E350X – Mid-range option for growing operations

- E1000 / E2000X – Commercial-grade, high-throughput models

All models are clean, quiet, and compliant—no emissions, no burn risks, and no headaches.

Final Takeaway

Choosing the right wire stripping machine isn’t just about budget—it’s about safety, speed, scrap value, and scaling potential.

StripMeister helps you strip smarter, safer, and more profitably. Find the right model and make the switch today.