Recycling Copper Wire: The High Cost of Skipping a Wire Stripper

Electricians often over-order wire to ensure they have enough for new construction or remodeling jobs. It’s common to have hundreds—sometimes thousands—of feet left over after a project. If you’re discarding or manually stripping that wire, you’re losing serious money.

Let’s break down how much you’re actually leaving on the table—and why using a StripMeister wire stripper can turn waste into revenue.

The Waste No One Talks About

During most jobs, electricians and contractors purchase extra 250-foot rolls of ROMEX wire. Across multiple projects, that leftover copper adds up—fast.

But to get top dollar for scrap, your wire must meet #1 Bare Bright copper standards: no insulation, solder, paint, or debris. If any residue remains, it drops in grade to #2 copper, which pays far less.

Here’s the kicker:

- #1 Bare Bright Copper: ~$4.00/lb

- Unstripped or #2 Copper: ~$1.5/lb

The difference adds up quickly when you’re dealing with hundreds or thousands of pounds.

Why Manual Stripping Fails

Many contractors try to save money by hand-stripping wire using knives or razors. But this method is:

- Time-consuming – You’re either doing it yourself or paying an employee overtime

- Unsafe – Utility knife injuries lead to workers’ comp claims and higher insurance premiums

- Inefficient – Manual stripping often damages copper or leaves insulation behind, disqualifying it from #1 classification

It’s labor-intensive, risky, and in most cases, ends up costing more in lost value than you might think.

The Math: How Much Are You Losing?

Let’s say you’ve saved 2500 feet of 1 AWG wire from past jobs.

| Wire Type | Feet | Revenue at $4.00 / lb (2025) |

|---|---|---|

| 1 AWG | 2500 | $ 2554.82 |

If sold unstripped at $1.5/lb, you’d only make about $950. That’s a difference of over $1500 in lost value.

StripMeister to the Rescue

With a StripMeister wire stripper, you process copper faster, safer, and more profitably. Even used or dirty wire can be stripped down to clean, shiny copper ready for resale.

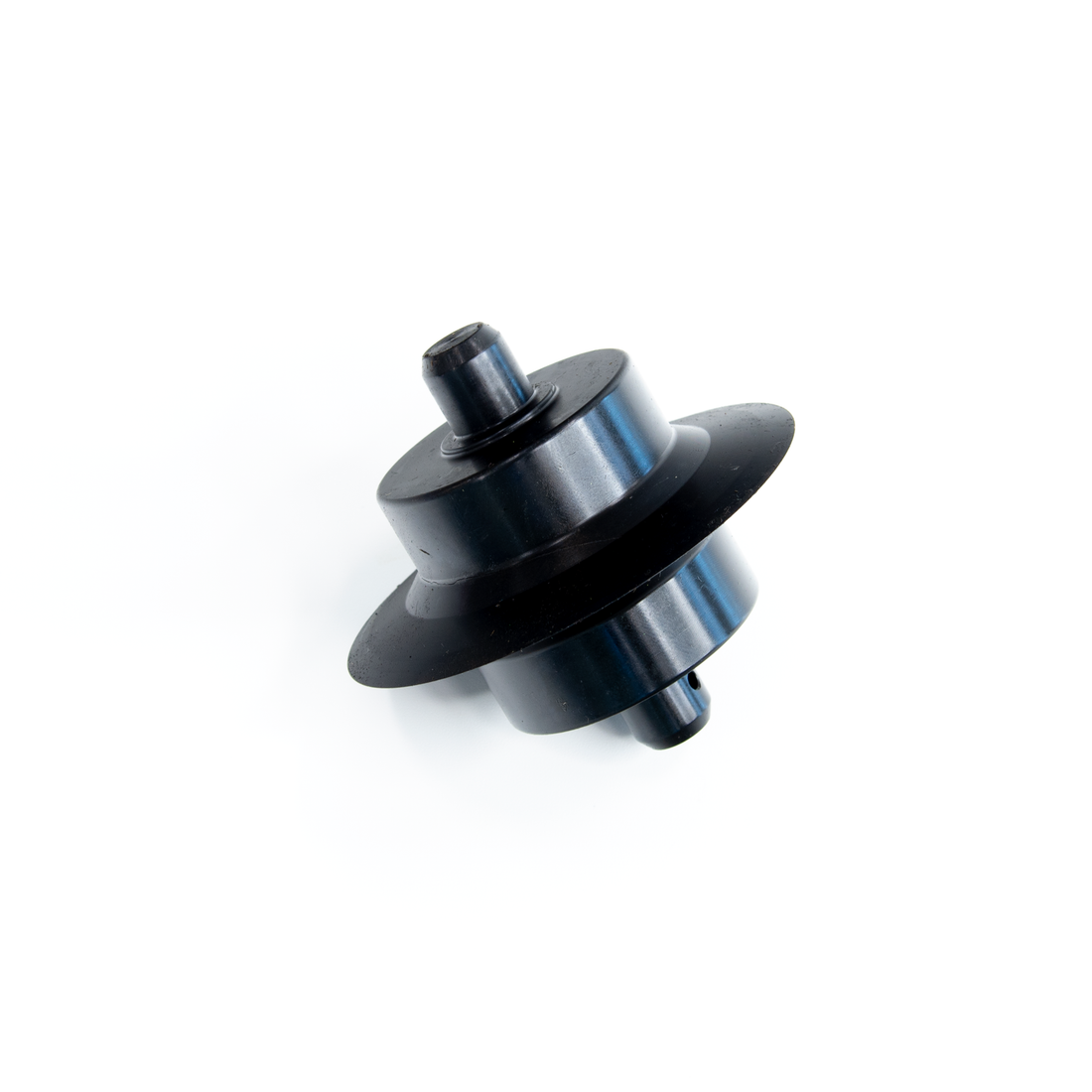

The StripMeister E2000X, for example, features:

- 1 HP motor with high torque

- Variable speed for precision control

- Capability from 14-gauge to 2000 MCM

- Consistent performance for daily high-volume use

In many cases, you’ll pay off the machine in just one job’s worth of scrap.

Frequently Asked Questions

Why is manual wire stripping less profitable?

Manual methods often leave insulation or damage the copper, lowering its grade. Plus, the time and labor involved reduce your ROI significantly compared to using a machine.

What qualifies copper as #1 Bare Bright?

It must be clean, shiny, uncoated, and free from insulation, paint, solder, or other contaminants. StripMeister machines help consistently achieve this standard.

Is a wire stripping machine worth it for small operations?

Yes. Even low-volume users benefit from safer, faster stripping. Most StripMeister owners see ROI within a few jobs and continue earning pure profit afterward.

Can one machine handle different wire sizes?

Absolutely. Models like the StripMeister E2000X handle a wide range—from 14 AWG to 2000 MCM—making them versatile for any scrap or electrical application.

Final Word: Turn Waste Into Wealth

Manual stripping costs you time, money, and safety. A StripMeister machine helps you reclaim your copper at full value—with zero cuts, no downtime, and maximum efficiency.

Whether you’re rewiring homes or running a commercial crew, StripMeister helps you strip smarter—and profit more.