Quick Answer: A good wire stripper should be easy to use, built to last, and handle different wire types without constant jams or adjustments. Look for smooth feeding, consistent results, and reliable performance that saves you time and protects your copper. Quality machines pay for themselves quickly through faster work and better recovery.

Why Choosing the Right Wire Stripper Matters

Stripping wire by hand is slow, tiring, and risky. The right machine changes everything. You finish jobs faster, recover more copper, and avoid the constant frustration of jams and damaged wire.

A good wire stripper isn't just about speed. It's about getting clean results every time without wasting material or your energy.

Ease of Use: Keep It Simple

The best wire strippers work without complicated steps or constant fiddling. You should be able to adjust the blade depth easily and switch between wire sizes without losing time.

Look for machines with clear guide systems that show you exactly where to position your wire. Simple adjustments mean less downtime and more stripping.

If setup feels confusing or takes forever, you'll waste time on every batch. Keep it straightforward.

Build Quality: Made to Last

Quality wire strippers use durable materials that hold up to daily use. Metal construction and heat treated tool steel blades provide reliable performance.

StripMeister wire stripping machines use aircraft grade aluminum and steel reinforcement for the body. Hardened, precision machined blades maintain sharpness through repeated use.

Solid construction means fewer repairs and more consistent cutting. You want a machine that feels sturdy when you use it.

Smooth Feeding: No More Jams

Nothing kills productivity like wire that slips, tangles, or gets stuck. Good feeding systems grip the wire firmly and pull it through without drama.

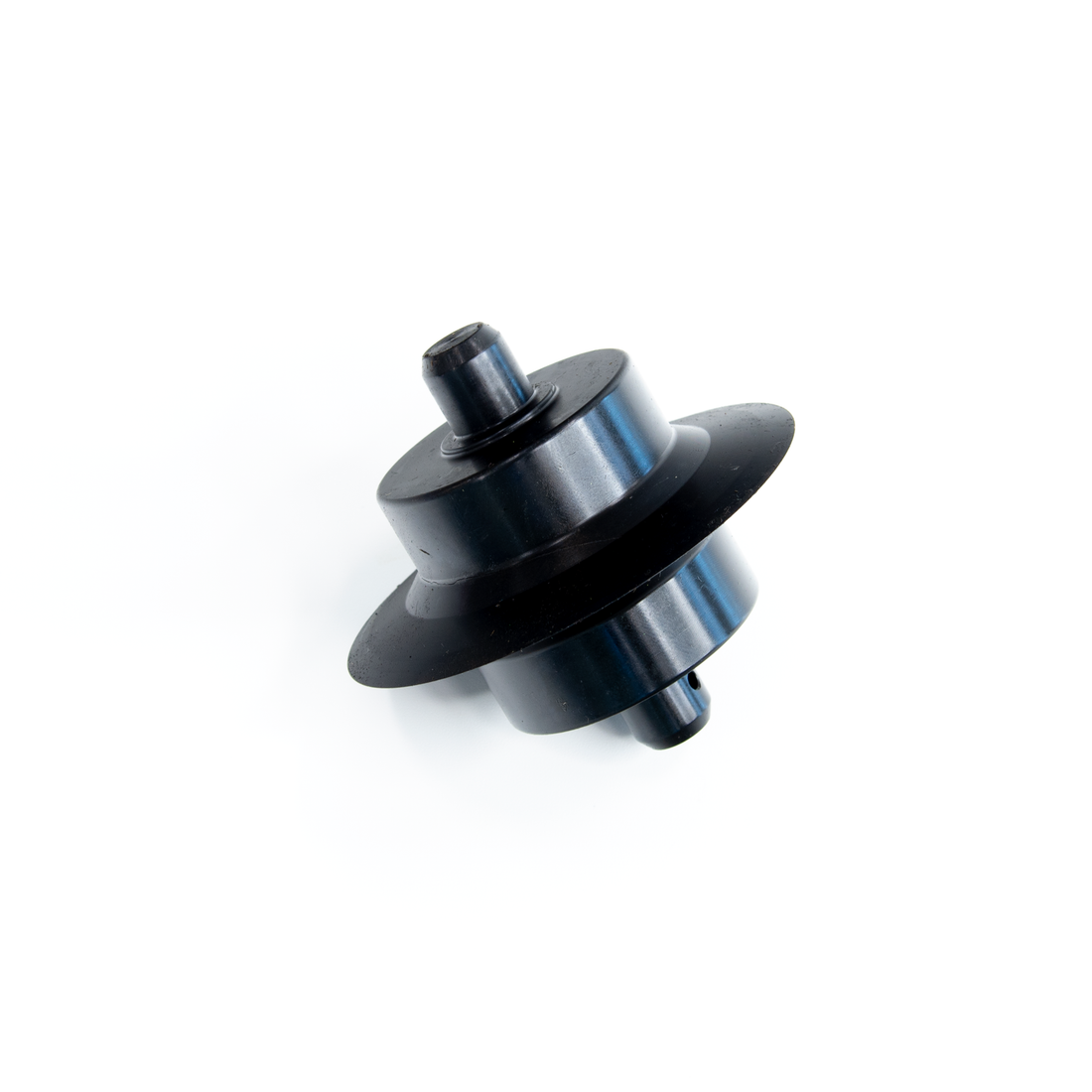

ULTRA GRIP Feeder Technology is standard on all StripMeister models. It handles kinked or twisted wire without constant babysitting. Smooth automatic feed means you spend your time stripping, not clearing jams.

The difference between a frustrating machine and a reliable one often comes down to how well it feeds wire.

Consistent Results Every Time

A quality wire stripper delivers the same clean cut on every piece of wire. Consistent depth control protects your copper and maintains the highest grades.

You shouldn't have to guess or constantly readjust. Once you set the blade depth correctly, it should stay that way through the entire batch.

Inconsistent machines damage copper, create waste, and cost you money at the scrapyard.

Reliability: Machines That Show Up

Professional work demands equipment you can count on. Reliable wire strippers handle heavy use without breaking down or losing performance.

Look for machines backed by real support. When you have questions or need parts, help should be available.

Equipment that quits on you mid job isn't a bargain at any price. Reliability means finishing the work you started.

Long Term Value: Buy Once, Cry Once

Quality costs more upfront but saves money over time. Machines built with durable materials and quality engineering provide better value through consistent performance.

Low maintenance and solid construction mean less downtime and fewer replacement costs. The right machine pays for itself through speed, durability, and consistent performance.

Calculate the real cost over years, not just the purchase price.

StripMeister: Built for Professionals

StripMeister machines handle wire from small residential cable to large industrial sizes. Every model includes features that matter: ULTRA GRIP Feeder Technology, precision blade control, and durable construction.

All StripMeister electric models are assembled in Canada with quality materials and backed by real support. From drill powered options to electric models, the focus stays the same: reliable performance that professionals count on.

FAQ: Common Questions About Wire Strippers

Quality wire strippers handle Romex, THHN, aluminum wire, stranded cable, solid wire, and twisted wire. All StripMeister models include a built-in Romex adapter and work with different wire types when the blade depth is properly adjusted. The machine should adapt to your wire, not the other way around.

Look for metal construction, heat treated blades, and quality engineering. Machines built with durable materials handle daily use without breaking down. StripMeister electric models use aircraft grade aluminum and steel reinforcement with hardened, precision machined tool steel blades.

Smooth feeding prevents jams and keeps work moving. Good feeder technology grips kinked or irregular cable securely without slipping. StripMeister machines use ULTRA GRIP Feeder Technology as standard on all models to handle twisted and tangled wire. Less time clearing jams means more time stripping.

Burning insulated wire is illegal and unsafe. Mechanical stripping is the compliant, emission free method that protects both you and the environment. Controlled cutting depth and consistent operation reduce risk compared to manual knife stripping. Professional wire strippers provide safer, more efficient copper recovery.

Good electric wire strippers require minimal care. Check blade wear periodically, clean rollers after sessions, and lubricate moving parts occasionally. With proper use, quality machines provide years of service with basic maintenance. Simple upkeep keeps performance consistent.