Wire Stripping Methods: From Manual Cuts to Professional Mechanical Stripping with StripMeister

When recycling copper wire, method determines safety, compliance, and scrap value. Mechanical stripping is the compliant, emission-free method that delivers clean, bright copper for maximum scrap payouts. StripMeister wire stripping machines eliminate the risks, inefficiencies, and legal issues associated with manual methods or burning, delivering precision copper recovery backed by Made in Canada engineering.

The 5 Methods People Try (and What Actually Works)

1. Utility Knife (Slit-and-Peel)

Manual stripping with a utility knife involves slitting the insulation jacket lengthwise and peeling it away from the conductor.

Why people try it: No equipment cost; works for small samples or emergency repairs.

Why it fails: Slow, unsafe, and prone to nicking the copper core. Nicked copper gets downgraded at scrap yards, reducing payout. Repetitive hand motion causes fatigue and increases injury risk.

2. Hand-Crank Stripping Devices

Hand-crank strippers clamp onto wire and use rotary motion to cut through insulation as the operator turns a manual crank.

Why people try it: More consistent than knife stripping; no power source required.

Why it fails: Physically exhausting for volumes beyond hobby-level projects. Inconsistent blade depth control leads to occasional copper damage. Setup time per wire gauge is significant.

3. Drill-Powered Strippers

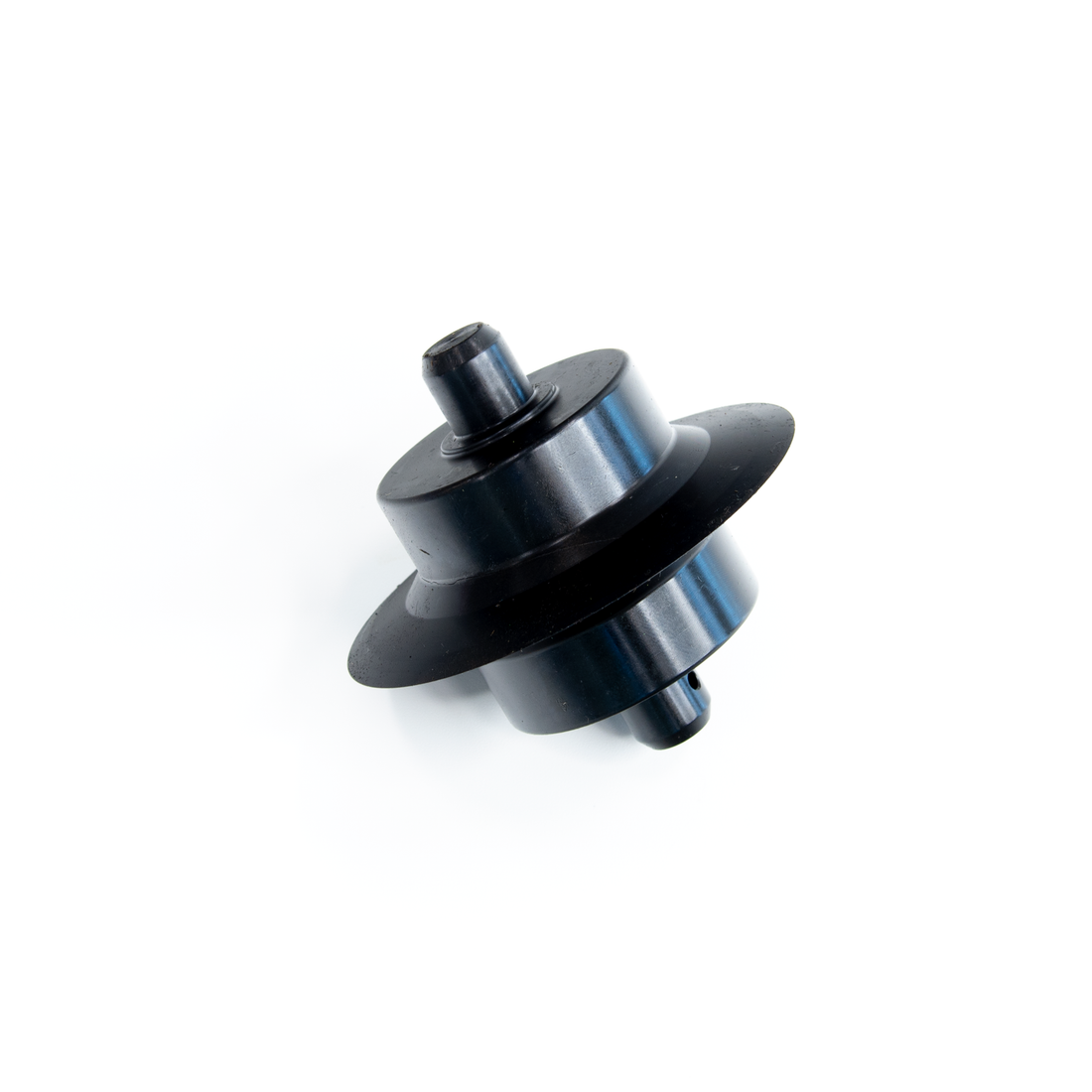

Drill-powered wire strippers attach to cordless drills and use rotary cutting to remove insulation. The StripMeister Original Pro is a drill-powered solution designed for #18 AWG to 250 MCM wire, with diameters from 0.08–0.79 inches (2–20.1 mm).

Why people try it: Faster than manual methods; portable and affordable for small to moderate batches.

Why it requires care: Drill RPM must be controlled (maximum 350 RPM recommended for the Original Pro). Torque consistency depends on drill battery charge. Operator must manually advance wire through the cutting assembly.

4. Electric Variable-Speed Wire Stripping MachinesPROFESSIONAL

Electric wire strippers use dedicated DC motors with variable speed controllers, engineered feed systems, and precision blade assemblies. StripMeister manufactures four electric models—E250 Pro, E350X, E1000, and E2000X—each CSA/TUV/CE approved and Made in Canada.

Why electric machines win:

Precision cutting: ULTRA GRIP Feeder Technology uses spiral-groove feeders that grip insulation at multiple contact points, reducing slippage and maintaining consistent feed pressure on twisted or kinked cable. The E350X features larger spiral-groove feeders that process wire faster at the same RPM as the E250 Pro.

Motor capacity matched to wire range:

- StripMeister E250 Pro: ¼ HP 90V DC motor, #18 AWG–250 MCM (0.08–0.79 inches / 2–20.1 mm)

- StripMeister E350X: ¼ HP 90V DC motor with gearbox and PWM controller, #18 AWG–500 MCM (0.08–1.043 inches / 2–26.5 mm), heavy-duty 15 mm drive shaft

- StripMeister E1000: ½ HP 90V DC motor, #18 AWG–1000 MCM (0.08–1.4 inches / 2–35.5 mm), adjustable speeds from 16–85 ft/min, high-torque automatic feed, quick knife-change system that auto-realigns to factory specifications

- StripMeister E2000X: 1 HP 120V DC motor, #18 AWG–2000 MCM (0.08–3.125 inches / 2–79.4 mm), dual-slider spiral feed for fast size transitions, emergency stop button for industrial safety

Compliance and build quality: All electric models are CSA/TUV/CE approved and Made in Canada. Frames are constructed from aircraft-grade aluminum alloy. Knife assemblies are precision-machined from hardened, heat-treated tool steel. All components are machined using 5-axis CNC milling technology for dimensional accuracy and long-term durability.

Copper recovery: Mechanical stripping preserves near-100% copper integrity, producing clean, bright copper that commands premium scrap pricing. No nicks, no oxidation, no downgrading.

5. Scaling Your Success: Choosing the Right StripMeister Model

StripMeister offers a progression path based on wire capacity and operational volume:

Original Pro

Drill-powered

#18 AWG–250 MCM

Portable, affordable for DIY and small batches

E250 Pro

Electric

Same wire range as Original Pro

¼ HP motor with ULTRA GRIP

E350X

Mid-Capacity

Up to 500 MCM

Larger spiral-groove feeders, 15 mm shaft

E1000

Industrial

Up to 1000 MCM

Hands-free automatic feed, 16–85 ft/min

E2000X

Heavy-Duty

Up to 2000 MCM

1 HP motor, dual-slider feed, emergency stop

Every model is designed to maximize copper recovery, reduce labor, and eliminate the compliance risks associated with burning insulated wire.

Why Mechanical Stripping Wins for Compliance & Copper Value

Mechanical stripping is the compliant, emission-free method for copper recovery. Burning insulated wire releases toxic fumes including dioxins and heavy metals, violates air quality regulations in most jurisdictions, and oxidizes copper surfaces, reducing scrap value. Manual knife stripping risks nicking conductors, which downgrades copper at scrap yards.

StripMeister machines eliminate both problems. ULTRA GRIP Feeder Technology maintains consistent blade contact without damaging copper cores. Variable speed control on electric models allows operators to match feed rate to insulation thickness and wire rigidity. The result is clean, bright copper that commands premium pricing.

All StripMeister electric models—E250 Pro, E350X, E1000, and E2000X—are CSA/TUV/CE approved, meeting North American and European safety standards for electrical components and operator interfaces. Made in Canada manufacturing ensures traceability, quality control, and adherence to labor and environmental standards.

For contractors, scrap processors, and recyclers, compliance isn't abstract—it's the difference between operating legally and facing enforcement action. Mechanical stripping removes that uncertainty while maximizing copper recovery per pound processed.

The Bottom Line

Manual methods and drill-powered strippers have hidden costs: lost time, physical fatigue, nicked copper, and downgraded scrap payouts. Electric wire stripping machines deliver:

- Faster processing through ULTRA GRIP Feeder Technology and variable speed control

- Cleaner results with precision blade depth adjustment and consistent feed pressure

- Higher payouts from clean, bright copper with no oxidation or surface damage

- Long-term ROI through aircraft-grade aluminum construction, tool-steel components, and Made in Canada durability

Whether you're stripping Romex on jobsites, processing feeder cables from demolition projects, or recovering copper from utility wire at scale, StripMeister provides the capacity, control, and compliance professional operations require.