Copper has long been one of the most valuable metals in the recycling industry. Its excellent conductivity and durability make it essential for electrical wiring, plumbing, and countless industrial applications. But when copper wire reaches the end of its life, how you recycle it can make a big difference in both the payout you receive and the time you spend.

The question most scrappers and contractors ask is simple: should I strip my copper wire, or just recycle it as is? The answer depends on the tools you use—and whether you’re working with a dedicated wire stripping machine.

Why Copper Recycling Matters

-

High value per pound: Clean, bare copper (“#1 Bright”) fetches the highest prices at scrapyards.

-

Environmental benefits: Recycling copper requires up to 85% less energy than mining new copper.

-

Rising demand: With renewable energy, electric vehicles, and infrastructure upgrades, copper demand is projected to grow steadily over the next decade.

Stripping your wire can upgrade your copper from a lower grade (insulated or mixed) to #1 or #2 copper, significantly improving your return.

Recycling Copper Without a Wire Stripper

The simplest method is to sell insulated wire directly to a scrapyard. While it saves time, you’ll often receive a much lower price per pound because the yard must process it themselves.

Pros:

-

No upfront equipment investment.

-

Quick and easy for small amounts of scrap.

-

Safe—no risk of improper blade use.

Cons:

-

Lower payout due to insulation weight.

-

You have no control over copper grade.

-

Missed opportunity to maximize ROI when copper prices are high.

For example, 100 lbs of insulated wire may only net you the value of 60–70 lbs of copper once the insulation is factored in.

Recycling Copper With a Wire Stripper

Using a wire stripping machine, such as those from StripMeister, transforms insulated wire into clean, bare copper ready for top-tier pricing. Instead of paying the scrapyard to do the work, you capture the margin yourself.

How It Works

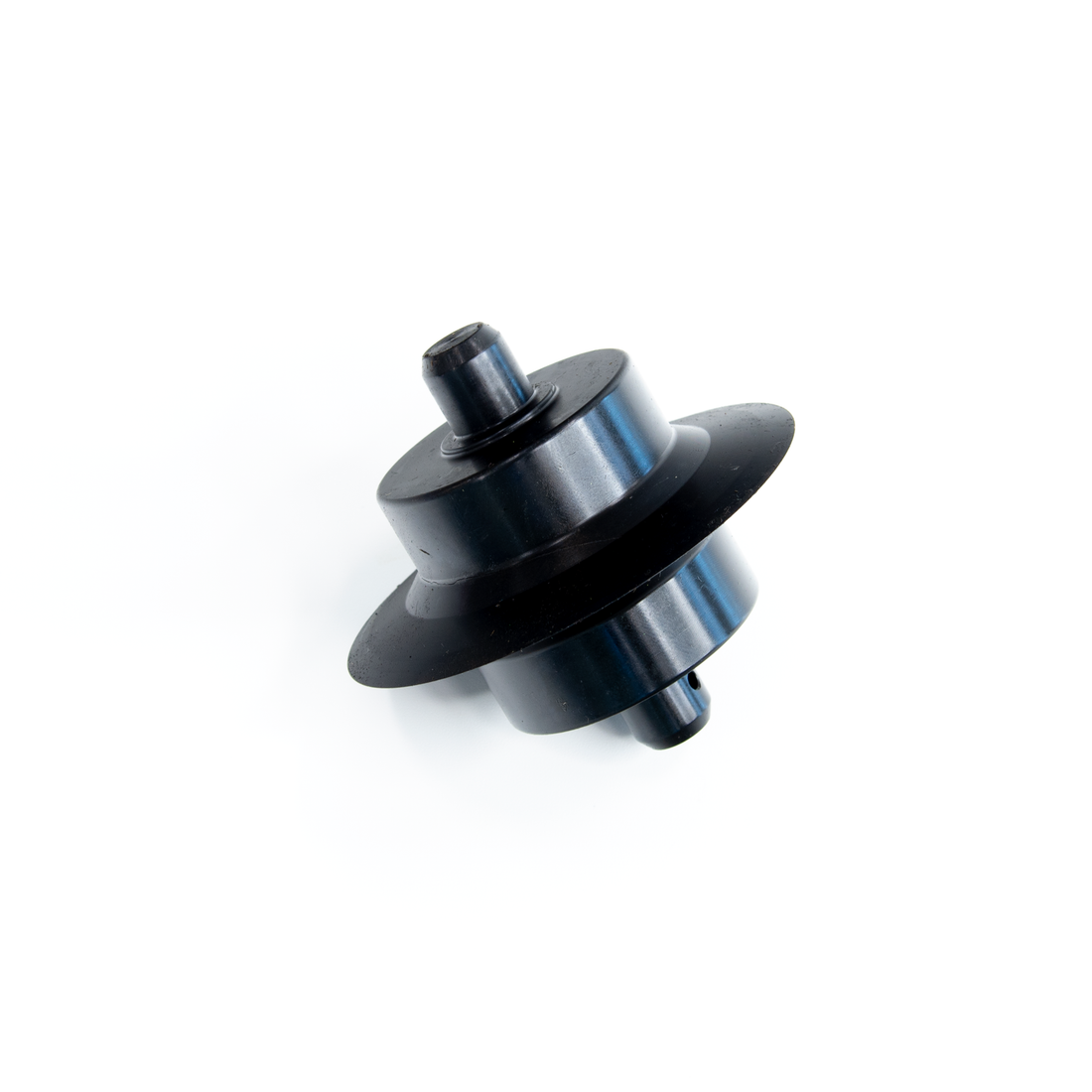

Wire strippers are designed to cut through insulation without damaging the copper core. Models range from manual crank machines for hobbyists to electric, variable-speed machines that handle hundreds of feet per minute.

For example, StripMeister’s E1000 uses a variable-speed motor with heavy torque to process everything from household wiring to large industrial cable, feeding wire smoothly with stainless steel guides for perfectly centered cuts.

Pros:

-

Higher profits: clean #1 copper can sell for up to double the price of insulated copper.

-

Fast and consistent processing, especially with electric strippers.

-

Long-term ROI: machines often pay for themselves after a few batches of scrap.

Cons:

-

Upfront investment in equipment.

-

Slight learning curve in setup and operation.

-

Requires workspace and basic safety precautions.

Safety and Best Practices

Whether stripping wire by hand or with a machine, follow these guidelines:

-

Always wear gloves and eye protection.

-

Secure the machine to a stable surface before use.

-

Adjust blade depth carefully to avoid nicking copper.

-

Keep work areas clean—copper shavings and insulation fragments can be sharp and hazardous.

Which Method Should You Choose?

-

Small, occasional batches? Selling insulated wire directly may be more practical.

-

Contractors, electricians, recyclers, or anyone handling wire regularly? Investing in a wire stripping machine makes sense. The boost in payout quickly outweighs the purchase price.

If your goal is to turn wire scrap into maximum profit, a wire stripper isn’t just a tool—it’s an investment in efficiency and higher returns.

Final Thoughts

Copper recycling will only become more valuable as global demand rises. By understanding the difference between recycling copper with and without a wire stripper, you can make smarter choices that fit your workflow, volume, and financial goals.

Whether you’re a hobby scrapper cleaning out your garage or a contractor processing cable from a demolition project, the right approach can turn copper wire from clutter into cash.