10 Smart Ways to Turn Scrap Wire into Profit

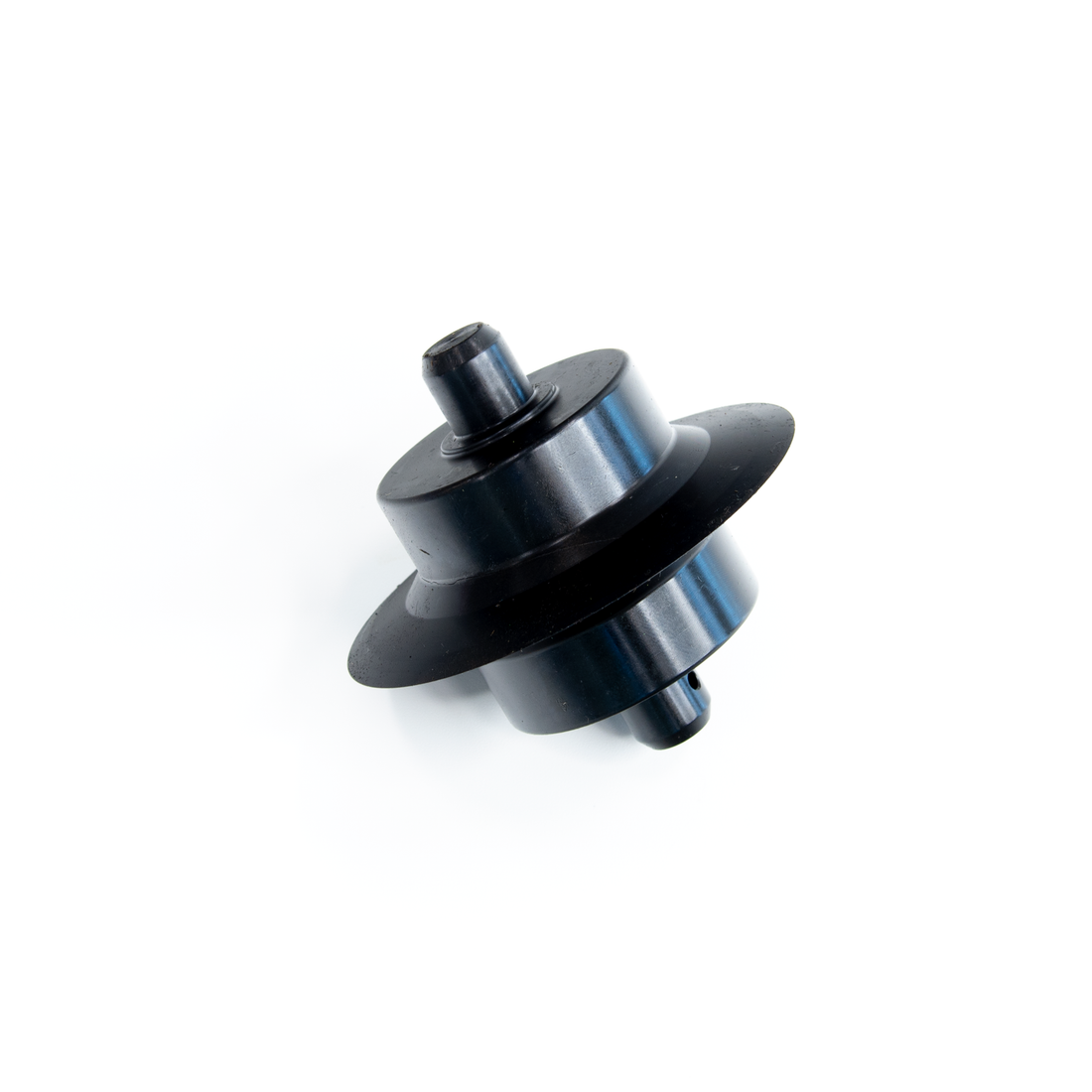

Using a StripMeister Original Automatic Wire Stripping Machine

Thinking about investing in an automatic wire stripping machine? Many scrappers, contractors, and recyclers are using the StripMeister Original to turn insulated wire into higher-value copper—faster and with less effort. Below are ten practical, real-world ways to make it pay.

10) Bid on Bulk Wire Lots at Auctions

Watch local auctions and online marketplaces for mixed wire bundles or teardown lots. With the StripMeister Original, you can process big batches efficiently and convert insulated material into higher-value copper grades (yard rules and grading apply).

9) Harvest Automotive Wiring

If you trade in junk vehicles, don’t leave wiring harnesses behind. Remove the harnesses and strip them. Moving material from automotive shred pricing to copper categories can materially improve your payout.

8) Tear Down Commercial Equipment

Restaurant appliances, commercial machines, vending units—older equipment often hides many pounds of insulated copper. Disassemble safely, recover the wire, and run it through your machine to boost returns.

7) Partner with Electrician Apprentices

Apprentices frequently keep demo and tear-out wire. Offer a fair price for their insulated scrap, then batch-strip it. You’re giving them time back while creating profit on your side.

6) CRT Degaussing Cable

For older TVs and monitors, degaussing loops can contain quality copper—but the insulation can be messy. Trim the pigtail section and feed the rest through the machine for quick, clean recovery. (Use proper PPE and recycling practices.)

5) Washer & Dryer Wiring Harnesses

If you’re hauling appliances, pull the harnesses before you sell as shred. Stripping the insulated copper typically beats leaving it in place.

4) Computer Power Supply Wire

When breaking down computers, don’t stop at boards. Remove power supplies, clip off connectors, and strip the leads. It’s a simple step that can move material from low-value categories to copper.

3) Short Offcuts, Solved

Short and odd-length pieces are a pain to strip by hand. Sort by thickness, batch them, and run them through the Original—small scraps turn into quick wins.

2) Cords You Couldn’t Profit From Before

Many light-gauge cords (e.g., long 16-gauge vacuum cords) aren’t worth hand-stripping. With automatic feeding and steady throughput, they become viable.

1) Make Romex® Work Harder

Romex is everywhere in North America. With a built-in adapter and fast feed rates, the StripMeister Original makes processing common house wire efficient—helping your material qualify for better grading at many yards (always check local criteria).

Why the StripMeister Original Pays Back

-

Built for daily use: Machined in North America from aircraft-grade aluminum and stainless components.

-

Clean, repeatable results: Precision knife and guided feed help center the cut and reduce waste.

-

Useful range: Designed for approximately #16 wire up to 250 MCM (about 0.100″/3 mm to 0.79″/20.1 mm diameter).

-

Peace of mind: Backed by a one-year warranty against manufacturing defects.

Bottom line: If you handle scrap wire regularly, the StripMeister Original Automatic Wire Stripping Machine helps you turn more of it into clean copper—faster, more consistently, and with less manual effort. Order yours today and start converting cable into value.