ULTRA GRIP FEEDER TECHNOLOGY

Jam-free, smooth feeding—even with twisted, mangled cable—so you strip faster with less hassle.

A MACHINE FOR EVERY CABLE

Coverage from fine gauges to big copper—pick the model built for your range.

PRECISION, CLEAN CUTS

CNC-machined, heat-treated tool-steel blade delivers consistent, accurate insulation removal.

BUILT TO LAST

Solid aircraft-grade aluminum body and stress-proof components stand up to years of use.

ROMEX-READY

Built-in adapter speeds up common household cable without extra setup.

MADE IN Canada

Designed and assembled here for quality, reliability, and support you can count on.

ULTRA GRIP FEEDER TECHNOLOGY

Jam-free, smooth feeding—even with twisted, mangled cable—so you strip faster with less hassle.

A MACHINE FOR EVERY CABLE

Coverage from fine gauges to big copper—pick the model built for your range.

PRECISION, CLEAN CUTS

CNC-machined, heat-treated tool-steel blade delivers consistent, accurate insulation removal.

BUILT TO LAST

Solid aircraft-grade aluminum body and stress-proof components stand up to years of use.

ROMEX-READY

Built-in adapter speeds up common household cable without extra setup.

MADE IN Canada

Designed and assembled here for quality, reliability, and support you can count on.

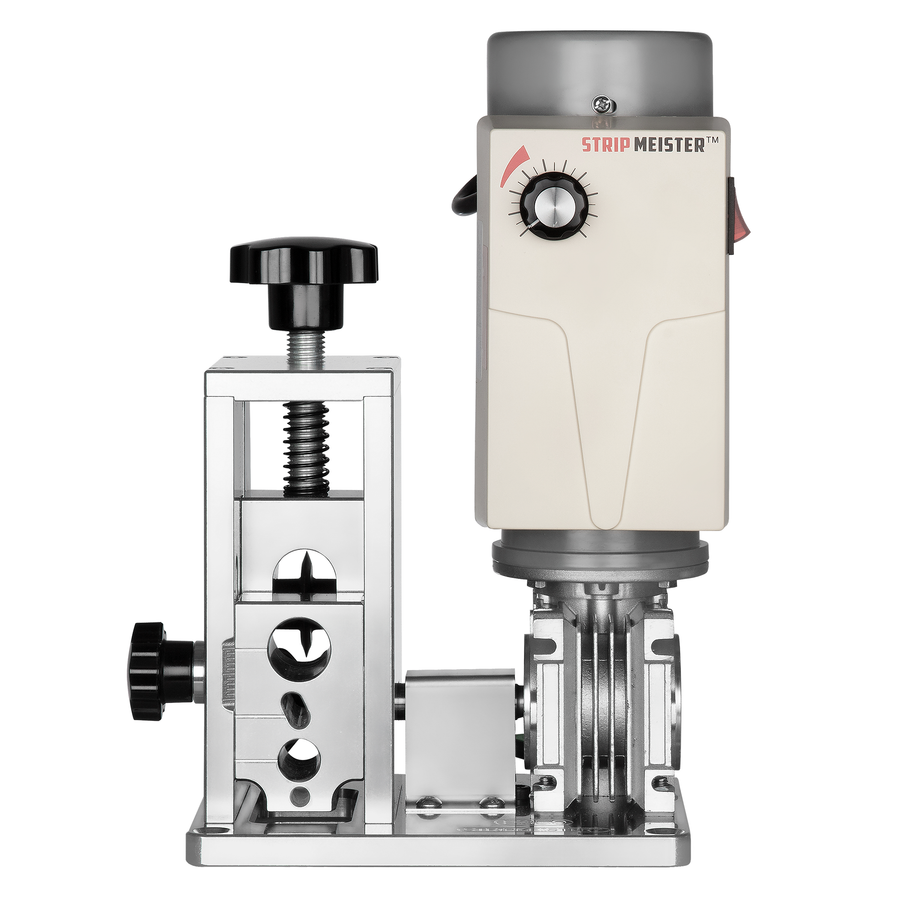

Our Wire Strippers

Precision that pays for itself

-

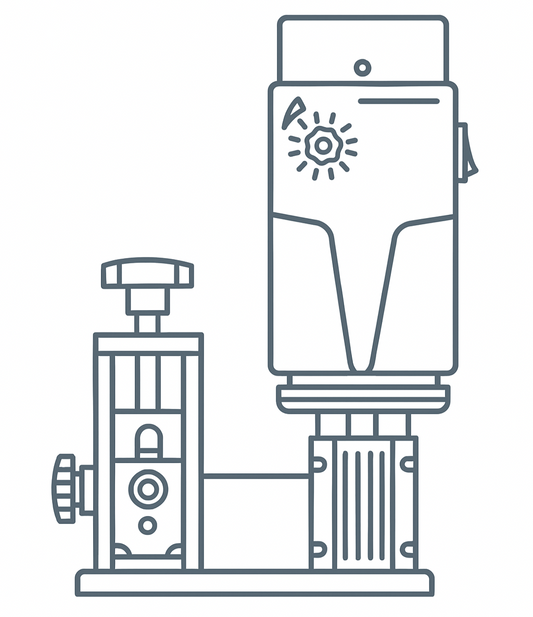

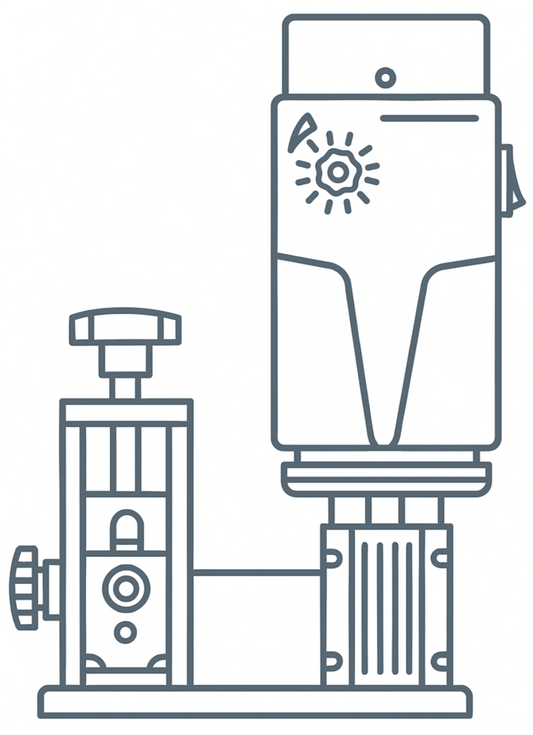

A premium, drill-powered Wire Stripper with a refined finish and a stainless-steel rear wire guide for straighter, jam-resistant feeding. ULTRA GRIP traction and a heat-treated blade deliver clean, centered cuts in a durable, aircraft-grade aluminum body.

-

A premium, electric automatic Wire Stripper with variable-speed control and a stainless-steel rear wire guide for steady alignment and hands-free throughput. ULTRA GRIP feeding and precision, heat-treated components produce clean, repeatable results with minimal downtime.

-

Fast, automatic stripping for everyday cable. The Ultra-Grip feeder keeps wires straight and untangled for clean, consistent strips with no slips or jams. Handles everything from 18 AWG up to heavy NM-B (Romex) so you turn scrap into cash quickly.

-

Step up the power for thicker, stubborn cables. Smooth variable speed delivers shiny, consistent strips job after job, with more torque and less waste. Ideal for busy shops that want cleaner results and bigger payouts.

-

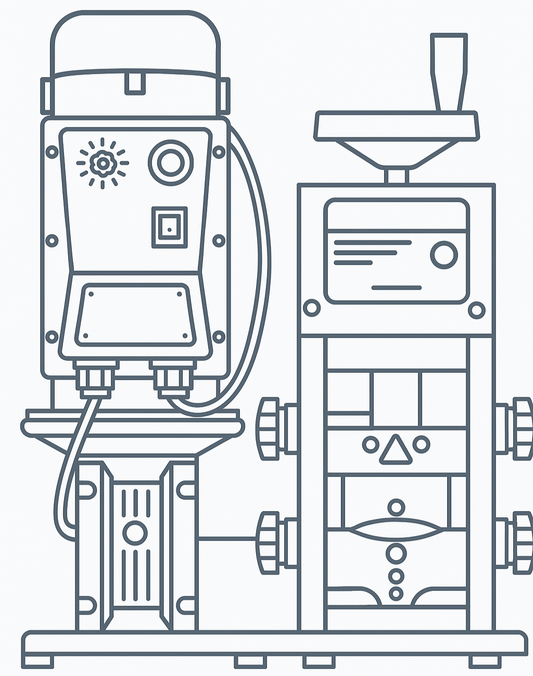

Industrial-grade performance for high-volume work. A 1 HP motor and spiral-groove drive rip through commercial copper and aluminum while the double guide and built-in Romex adaptor keep cuts precise. Designed for continuous duty to maximize recovery and uptime.

Wire Stripping Machines

Precision that pays for itself

Frequently Asked Questions

Which wire stripping machine is best for my needs?

The best wire stripper machine depends on your wire diameter range and processing volume. The StripMeister Original Pro handles #18 AWG to 250 MCM and operates with a standard drill, making it ideal for DIY users and small-batch stripping. For higher volumes, the E250 electric wire stripper covers the same range with a 1/4 HP DC motor and variable-speed control. If you work with larger cable up to 500 MCM, choose the E350X with its 1/4 HP motor and spiral-groove ULTRA GRIP feeder. The E1000 strips up to 1000 MCM and includes a built-in Romex adapter, while the E2000X handles cable up to 2000 MCM with a 1 HP motor and emergency stop for industrial applications.

Start by identifying your maximum wire diameter and whether you need portability or continuous operation. All StripMeister machines are CSA, TUV, and CE approved and manufactured in Canada.

What wire sizes can I strip—and how small is “too small”?

All StripMeister wire stripping machines process wire from #18 AWG to their maximum rated capacity. The Original Pro and E250 handle up to 250 MCM, the E350X up to 500 MCM, the E1000 up to 1000 MCM, and the E2000X up to 2000 MCM.

Wire smaller than #18 AWG is generally too small for mechanical stripping because the insulation becomes thin and the copper strands are fragile. The adjustable blade-depth and guide-hole system ensure clean cuts across the full range without damaging copper. ULTRA GRIP Feeder Technology assists with twisted or kinked cable on all current models.

How fast do the machines strip?

Stripping speed depends on wire diameter, insulation type, and setup. The drill-powered Original Pro operates at the speed of your drill, efficiently processing small to medium cables in manual batches. The E250 electric wire stripper includes variable-speed control for precise operation. The E350X uses a 1/4 HP motor and spiral-groove feeder for consistent feed rates. The E1000 offers an adjustable speed range of 16 to 85 ft/min, while the E2000X delivers industrial-grade performance with its 1 HP motor for high-volume stripping.

Setup time is minimal once the blade depth is calibrated: cut a sample wire, choose the correct guide hole, touch the knife off, and adjust until clean copper is visible. ULTRA GRIP feeders reduce slippage and maintain consistent tension.

Do StripMeister machines work with Romex®, aluminum, and stranded cable?

Yes. All StripMeister wire stripper machines handle Romex®, THHN, aluminum, and stranded cable. Each model includes a built-in Romex adapter for fast processing of residential and building wire. Every machine can strip stranded, solid, and twisted cables when the blade depth is properly adjusted. ULTRA GRIP Feeder Technology grips kinked or irregular cable securely.

Aluminum wire strips cleanly using the same setup as copper: select the smallest guide hole that fits, adjust the blade depth carefully, and run a test sample to ensure full insulation removal. Mechanical stripping is the legal, emission-free alternative to burning insulated wire.

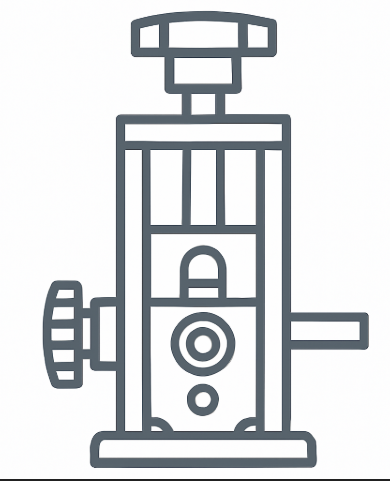

How do I set up a StripMeister wire stripping machine?

Setting up a StripMeister wire stripper machine follows a straightforward six-step process. First, prepare a small clipping of the same wire you will process. Second, choose the smallest guide hole that fits your wire diameter. Third, touch the knife off to establish initial contact without cutting. Fourth, set the wire guide to approximately 15° into the feed wheel with light pressure. Fifth, run the machine slowly and lower the knife until you just see copper. Sixth, strip the batch—ULTRA GRIP feeders help with kinked or twisted wire.

Once the blade depth is calibrated for a specific wire type, you can strip that wire continuously without readjustment. Test your settings on a sample length before processing large batches to maintain Bare Bright copper quality.

Is it worth stripping all types of insulated wire?

Stripping wire is worth it when the copper recovery value exceeds the time and labor cost. Bare Bright copper commands significantly higher prices than insulated copper wire at scrap yards. Thick, high-yield wire like Romex, THHN, and larger-gauge cable delivers the best return when stripped. Wire under #14 AWG can be stripped mechanically, but the return diminishes as wire diameter decreases.

A wire stripping machine dramatically improves profitability by reducing labor time and maintaining copper grade quality. Mechanical stripping prevents the copper damage that occurs with knife methods and eliminates the illegal and unsafe practice of burning insulation. Sort stripped copper by grade and keep it clean and dry to maximize scrap yard payouts.

What safety precautions should I follow when stripping wire?

Safe wire stripping starts with proper equipment and setup. Avoid loose clothing and remove jewelry before operating any wire stripper machine, as these can get caught in moving parts. Gloves are recommended for protection, but choose the right kind—thin fabric gloves are not suitable as they can get pulled into the feed system. Use professional-grade gloves made from thick materials like leather to safely handle conductors and sharp wire ends. Regularly grease your machine to ensure smooth operation and reduce resistance.

Mechanical wire stripping is dramatically safer than knife methods, reducing injury risk by up to 300%. If wire resists or jams, stop the machine and clear it properly rather than forcing it through. Test blade depth on a short sample before processing full batches to prevent copper damage. Maintain a clean, organized workspace and ensure the machine is securely mounted before operation.

How do I contact support (and when are you open)?

You can reach StripMeister support at 1-800-681-8494 or support@stripmeister.com for technical assistance with your wire stripping machine. Live support is available Monday to Friday, 8:00 AM to 4:00 PM EST.

Contact support for help with blade adjustment, feeder calibration, wire capacity questions, or troubleshooting. The technical team can guide you through setup and best-practice stripping techniques for your specific cable types.

What’s the warranty?

StripMeister products carry a 1-year warranty against defects for the original purchaser (proof of purchase required). Note: knife blades and feeders aren’t covered.

What’s your return policy?

Returns are accepted within 30 days of purchase; items must be unused with all original packaging. A 15% restocking fee applies and return shipping is the customer’s responsibility.

Pro Tips from the Founder

I’ve stripped miles of cable, and these three habits change everything. First, set up your StripMeister to handle every wire size and shape you’ll touch—no constant re-tuning. Second, lock in the right wire angle and blade depth so you cut jacket, not copper; clean cores mean better payout. Third, let the ULTRA-GRIP feeder do the work—steady feed, no slips, even on kinked wire. In a few minutes I show exactly how I dial it in here in Canada—simple tweaks you can repeat every day for faster runs, fewer jams, and cleaner copper from the very first pull.