Why Winter Is the Best Time to Strip Wire

Transform the off-season into your most profitable months with smart indoor wire processing. Winter slows outdoor collection but opens time for indoor copper preparation. Cold weather limits scrap gathering, yet the season creates opportunity for scrappers who shift focus from collection to processing.

Mechanical wire stripping indoors transforms stored material into higher-value Bare Bright copper without exposure or compliance risk. Smart scrappers use winter months to build stockpiles of clean copper that can be sold when spring rates improve.

Indoor stripping eliminates weather delays and maintains productivity regardless of temperature. Mechanical methods ensure precision and safety year-round, turning downtime into profitable preparation work.

Winter Challenges—and Opportunities—for Scrappers

Cold weather reduces outdoor scrap collection activity as construction sites slow and jobsites close for the season. Scrap yards often see reduced traffic during winter months, creating opportunity for prepared sellers who arrive with clean, processed copper.

Winter months allow scrappers to focus on processing stored wire for higher-value Bare Bright copper. Indoor work eliminates weather exposure while maintaining consistent output. Mechanical stripping is safe for garage, basement, or shop operation throughout the season.

Scrappers who process wire in winter build inventory that can be sold strategically when copper prices or scrap yard demand improves. Clean copper maintains its quality during storage, unlike insulated wire that accumulates dirt and moisture.

The Problem with Outdoor Stripping in Cold Weather

Outdoor burning or hand-stripping is unsafe and non-compliant. Burning insulated wire is illegal and generates toxic smoke regardless of season. Cold temperatures make insulation brittle and harder to remove manually, increasing effort and reducing efficiency.

Manual tools become less effective in winter conditions. Knife stripping creates safety hazards that worsen with cold-stiffened materials. Hand fatigue increases in cold environments, slowing production and raising injury risk.

Why Mechanical Stripping Works Year-Round: Temperature does not affect machine performance or blade adjustment accuracy. Indoor operation eliminates exposure to weather conditions that reduce manual stripping effectiveness.

Mechanical Stripping: The Ideal Winter Workflow

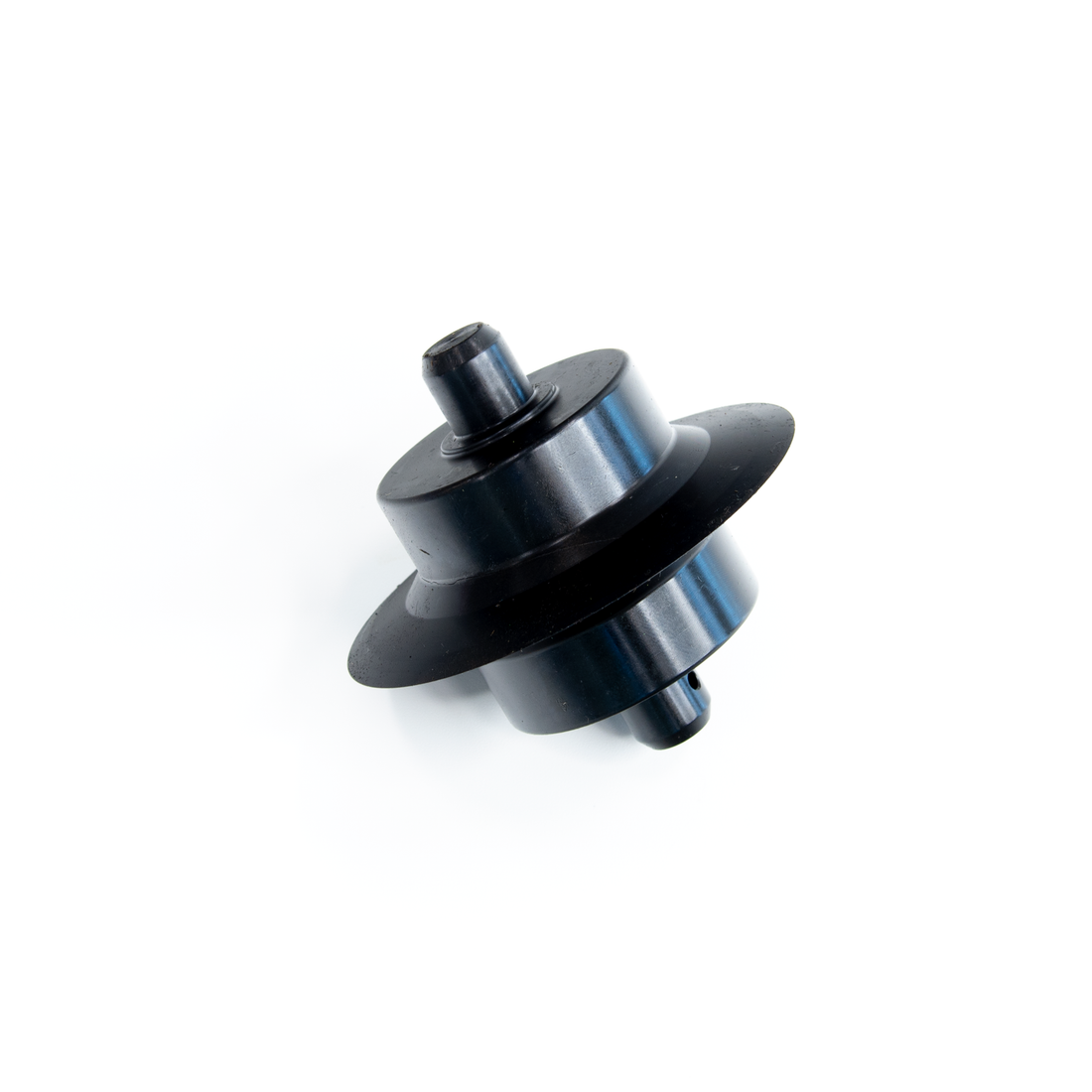

All StripMeister machines operate cleanly indoors. Electric models plug into standard household outlets for convenient setup. Drill-powered models provide reliable performance with any standard drill.

ULTRA GRIP Feeder Technology ensures jam-resistant operation even with kinked or frozen wire. The feeder grips twisted cable securely and maintains smooth feed pressure regardless of wire condition. Cold-stiffened insulation does not prevent proper blade contact or complete removal.

Compact sizes fit garage, basement, or shop setups. The E250 weighs 20 pounds and measures 14 × 11 × 17 inches, making it suitable for workbench mounting in limited space. All models are engineered and assembled in Canada for reliable winter operation.

Setup Guide for Indoor Stripping

Follow the official six-step setup method for any StripMeister model:

- Prepare a small clipping of the same wire

- Choose the smallest guide hole that fits

- Touch the knife off (initial contact without cutting)

- Set the wire guide to ~15° into the feed wheel with light pressure

- Run slowly and lower the knife until copper is just visible

- Strip the batch; ULTRA GRIP feeders help with kinked or twisted wire

This setup method works consistently regardless of season or wire temperature. Indoor operation protects blade adjustment from temperature fluctuations that could affect outdoor equipment.

Choosing the Right Machine for Winter Use

StripMeister Original Pro

Ideal for hobbyists and light-volume scrappers using a drill indoors. Handles wire from #18 AWG to 250 MCM with precision-machined tool-steel blade. Compact design requires minimal bench space and operates on any standard drill.

StripMeister E250 and E350X

Plug-and-play electric models with variable-speed control. The E250 features a 1/4 HP fan-cooled DC motor and handles wire from #18 AWG to 250 MCM. The E350X uses larger spiral-groove feeders and a heavier 15mm drive shaft for wire up to 500 MCM. Both plug into standard 110V household outlets and include CSA/TUV/CE safety approval.

StripMeister E1000 and E2000X

Built for high-volume recyclers processing large stockpiles indoors. The E1000 features a 1/2 HP motor with 16–85 ft/min variable speed range and handles wire up to 1000 MCM. The E2000X strips wire up to 2000 MCM with a 1 HP motor and emergency stop function. Both models include quick-change knife systems with automatic realignment.

All models are engineered and assembled in Canada with ULTRA GRIP Feeder Technology standard. Built-in Romex adapter and wire reference indicators reduce setup time between different wire types.

ROI and Efficiency Gains During Off-Season

Scrap yards pay more for Bare Bright copper than insulated wire. Clean wire stripped in winter can be stockpiled for spring sale when copper prices or scrap yard demand improves. Bare Bright copper maintains its grade during storage when kept dry and clean.

Time saved on manual stripping translates into higher throughput per hour. Electric models process wire at consistent feed speeds without hand fatigue or repetitive motion strain. Labor reduction allows operators to focus on quality control and material sorting rather than physical stripping effort.

Quick ROI: Machines pay for themselves quickly through higher copper yields and reduced downtime. The combination of labor savings and grade improvement creates compounding value over multiple processing sessions. Precision blade adjustment maintains highest copper grades while maximizing recovery value.

Safety and Comfort: Indoor Advantages

No fire risk or weather exposure during indoor mechanical stripping. Mechanical cutting is safe and produces clean results. Controlled indoor operation provides consistent performance throughout winter months.

CSA/TUV/CE safety approval ensures reliability during continuous operation on electric models. Fan-cooled motors maintain consistent performance during extended winter processing sessions. Variable speed control allows adjustment for different wire types without compromising safety margins.

Controlled indoor temperature protects blade precision and maintains operator comfort. Stable environment prevents material handling issues caused by frozen or moisture-laden cable. Indoor lighting and workbench access improve setup accuracy and quality control compared to outdoor processing.

Frequently Asked Questions

Yes. All models operate safely indoors, making them ideal for winter use. Electric models plug into standard household outlets. Drill-powered models work with any standard drill for convenient indoor operation.

Cold insulation can stiffen, but ULTRA GRIP Feeder Technology maintains smooth, jam-resistant operation. The feeder grips twisted and kinked cable securely regardless of temperature. Blade adjustment remains precise in stable indoor environments.

The E250 or Original Pro provide excellent control and performance for low to mid-volume users. Both handle wire from #18 AWG to 250 MCM. The E250 offers plug-and-play electric operation with variable speed control.

Processing wire in off-season builds stockpiles of Bare Bright copper that can be sold at better spring rates. Time spent preparing clean copper during slow months converts to higher payouts when market conditions improve.

Keep blades clean, lubricate moving parts occasionally, and store machines in dry, temperature-stable areas. Check blade wear after every few hundred pounds of wire. Clean feeders and remove insulation residue after each session to maintain smooth operation.