No products in your cart.

The wire stripper machine has been around for a while now, yet some still haven’t discovered the many benefits of this powerful device. You could be missing out on serious profits from recycling copper and aluminum wire. The first step to find out how to make money from this convenient cable stripping machine is to learn what it is and how to get it.

What is a Wire Stripper Machine?

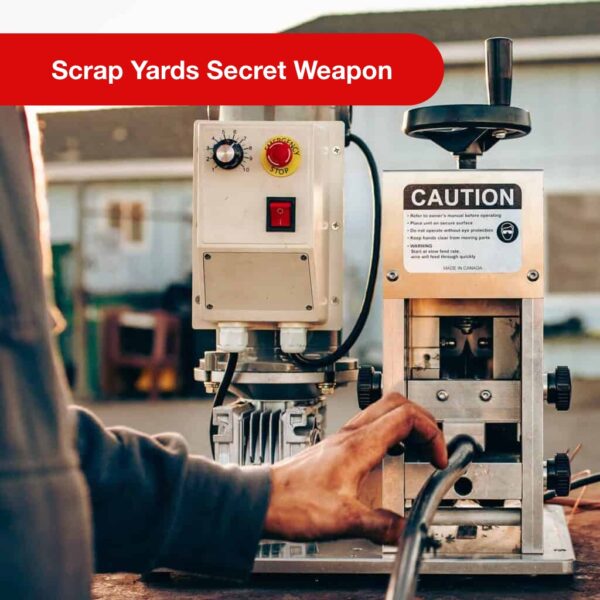

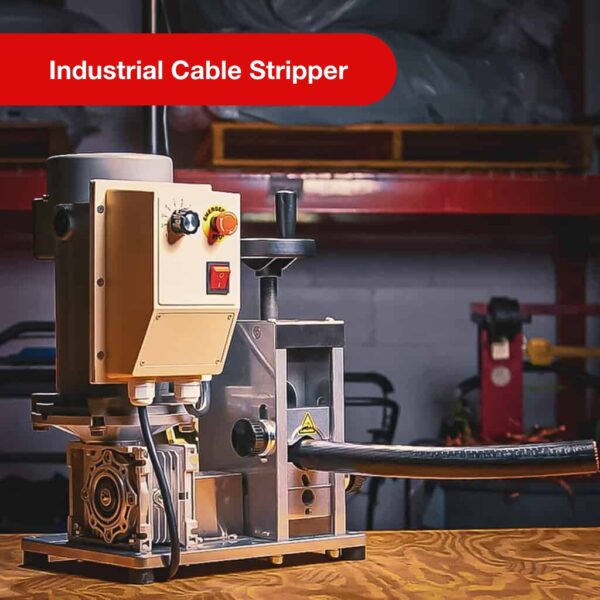

Sometimes referred to as an automatic wire stripper, the wire stripper machine is a relatively compact device that allows for the quick and easy separation of valuable wire from its protective casing and insulation. If done by hand, you would need a wirecutter and some kind of flat blade to make incisions and tear off the casing by hand. This method works, but it takes far more time and can be very frustrating.

The wire stripper machine dramatically cuts down on time by providing a surface made specifically to cut wire from its insulation. A hole or opening is available, usually with various sizes to accommodate different types of wire. The end of the wire to be cut is inserted and a spinning blade inside the machine creates a clean, length-wise incision along the exterior. The wire can then be easily pulled out and recycled.

What’s the Point of Stripping Wire?

If you don’t care about making money when you recycle, then the quickest way to go about the process is to turn in wire as is with its insulation intact. The problem with this approach is that you will make far less money. Those who use a wire stripper machine often find that they earn 3 to 4 times more for their wire than those who do nothing with it before recycling. You will also save the recycling center time by eliminating the wire separation step.

What Are the Drawbacks of Buying a Wire Stripper Machine?

There are really only two drawbacks to buying a wire stripper machine. First being that you will have to invest a little bit of cash up front to purchase the unit. Don’t worry about the price, though. It’s really an investment rather than an expense because you will quickly earn back what you paid out and then some.

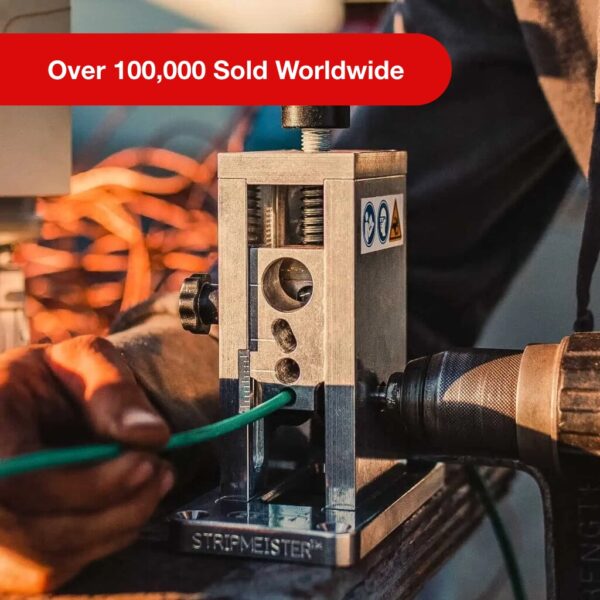

The other drawback is the need to occasionally replace the blade. Any cutting surface that is used often is eventually going to become dull. This generally takes a very long time when the wire stripper machine is used as recommended by the manufacturer. It’s also an expense that is easily covered by cash earned from recycling bare wire. The positive side is, with the StripMeister™, your blade will last up to 10x that of most others.

How Can I Buy a Wire Stripper Machine?

If you’re ready to upgrade those old wirecutters to a practical cable stripping machine, consider starting on the internet. Many models are available and can be easily researched on the web. Always look for a website that offers good information on their product as well as easy access to FAQs, policies and model specs like www.stripmeister.com.

A quality wire stripper machine will generally cost a few hundred dollars, so make sure you shop carefully when browsing cheaper models. Some look appealing but come with cumbersome separate parts or aren’t made to industrial standards. When you invest in a cable stripping machine that will last, you will get far more out of the purchase.

Get your StripMeister™ today!

-

StripMeister E2000X Industrial Wire Stripping Machine

$1,799.00 Add to cart -

StripMeister E1000 Electric Automatic Wire Stripper Machine

$1,097.00 Add to cart -

StripMeister E350X Electric Automatic Wire Stripping Machine

$597.00 Add to cart -

StripMeister E250 Electric Automatic Wire Stripping Machine

$449.00 Add to cart -

StripMeister Original Drill Powered Wire Stripping Machine

$149.00 Add to cart