No products in your cart.

For many decades, the easiest way to recover scrap copper was to simply burn the casing off wires in an open fire and then collecting the resulting product. The problem with this method is that burning (or smoldering) the insulation off the wire in this manner is the single most contaminant processes of recovery, due to the fact that the plastic casing is burned at relatively low temperatures (between 250°C and 500°C), which results in an incomplete incineration and the release of pollutants and carcinogens into the atmosphere.

Some of these pollutants are polychlorinated dibenzo-p-dioxins (PCDD) and polychlorinated dibenzofurans (PCDF), which result from the catalysis of copper, together with carbon monoxide (CO), sulphur dioxide (SO2), polycyclic aromatic hydrocarbons, hydrogen chloride, heavy metals (including lead) and ash. These elements can contaminate not only the air, but also water and soil, leading to severe consequences both to the environment and the population!

Complete and utter ban on smoldering for recovery and recycling

It was because of this that the federal Clean Air Act of 1970 was amended in 1990 to add specific controls over 189 different toxic pollutants, including those generated by the burning of copper wire. The end result was a complete and utter ban on smoldering for recovery and recycling, an action that would be accompanied by hefty fines ($25,000 or more per day) and several years in prison (up to 5). To drive the point across in such a manner that no room for doubt would be allowed, there is currently a standing reward ($10,000) for those who report the burning of copper wires to the EPA.

This federal legislation, one of the most comprehensive in the world, was further enhanced by the creation of the Stockholm Convention on Persistent Organic Pollutants (signed by the United States in 2001), a global treaty that went into effect in 2004. Because of this, alternative methods had to be proposed for the proper treatment of copper wire for recycling, among which chopping, stripping, and high temperature incineration (above 850°C) were found to be the most adequate.

Cable Stripping as the Most Viable Alternative Process to Smoldering

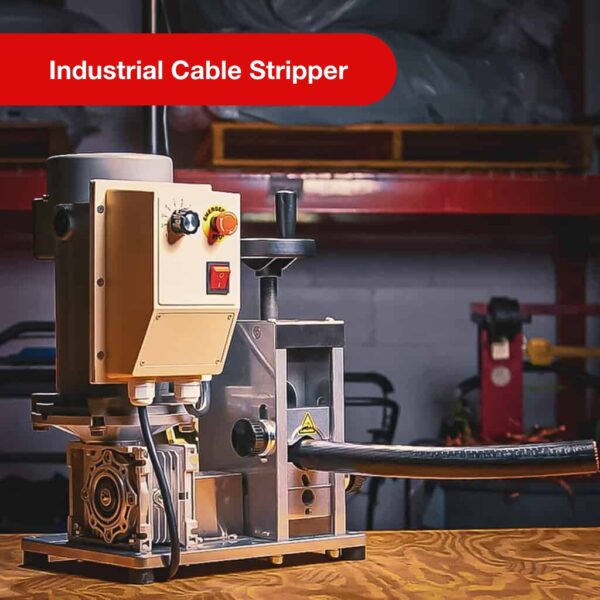

Out of all the options proposed, the most viable is cable stripping. While there are many reasons for its viability, the most important one is the ability to fully recover the metal without leaving traces of it on the plastic insulation, together with its low cost and the fact that pollutants such as PCDD and PCDF cease to be of any concern, given that the copper is not allowed to become a catalyst for them.

But all is not perfect in the world of cable stripping, and doing the job manually without a wire stripper can present serious risks to the person performing the task. Cuts are commonplace, together with the partial amputation of fingers, and let’s not even consider the time it takes to get the job done. In short, manual stripping is time consuming and dangerous, which can put a big dent into profits.

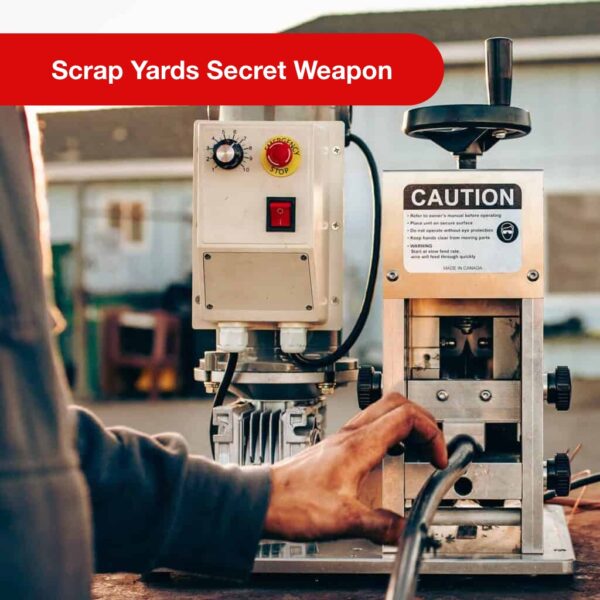

On the other hand, an industrial wire stripping machine can prove to be the best investment of its kind, as it can handle individual strands of up to 200 feet per minute in a wide range of diameters.

Maximizing Profit while Cutting Costs

As it is well known, scrapyards will pay much less for unstripped wire. This is because they have to go through the stripping process themselves, with the same issues that were mentioned previously (lost time, potential hazards, etc.). To maximize profits, the best way to go about business is to deliver fully stripped wire.

When you invest in a stripping machine, you can increase your profits by well over 30% (depending on current prices for scrap copper). This means that you will recover the money you spent in a very short time, while reducing the costs generated by manual stripping (think of that trip to the ER you won’t have to make). The process itself will be much faster and production will increase, generating enormous benefits to your business and allowing for expansion.

All in all, given the fact that burning wire is illegal in the United States (as well as in Canada, the UK, and many other countries), and that you will face jail time if you so much as think of starting that fire, together with wanting to keep all of your fingers attached to your hands, an investment that will only give you positive returns is definitely one you will want to make.

-

StripMeister E2000X Industrial Wire Stripping Machine

$1,799.00 Add to cart -

StripMeister E1000 Electric Automatic Wire Stripper Machine

$1,097.00 Add to cart -

StripMeister E350X Electric Automatic Wire Stripping Machine

$597.00 Add to cart -

StripMeister E250 Electric Automatic Wire Stripping Machine

$449.00 Add to cart -

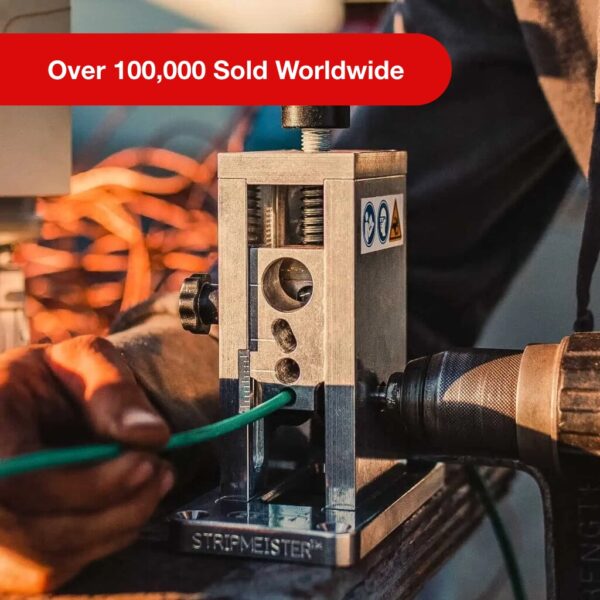

StripMeister Original Drill Powered Wire Stripping Machine

$149.00 Add to cart