No products in your cart.

Original

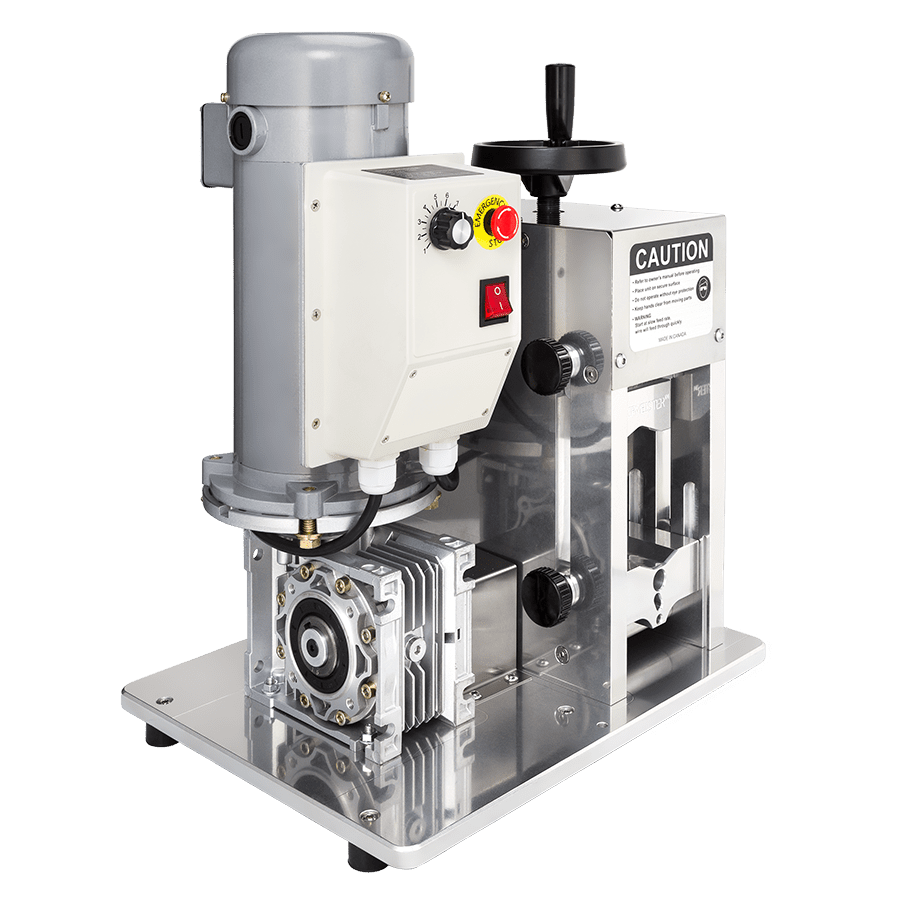

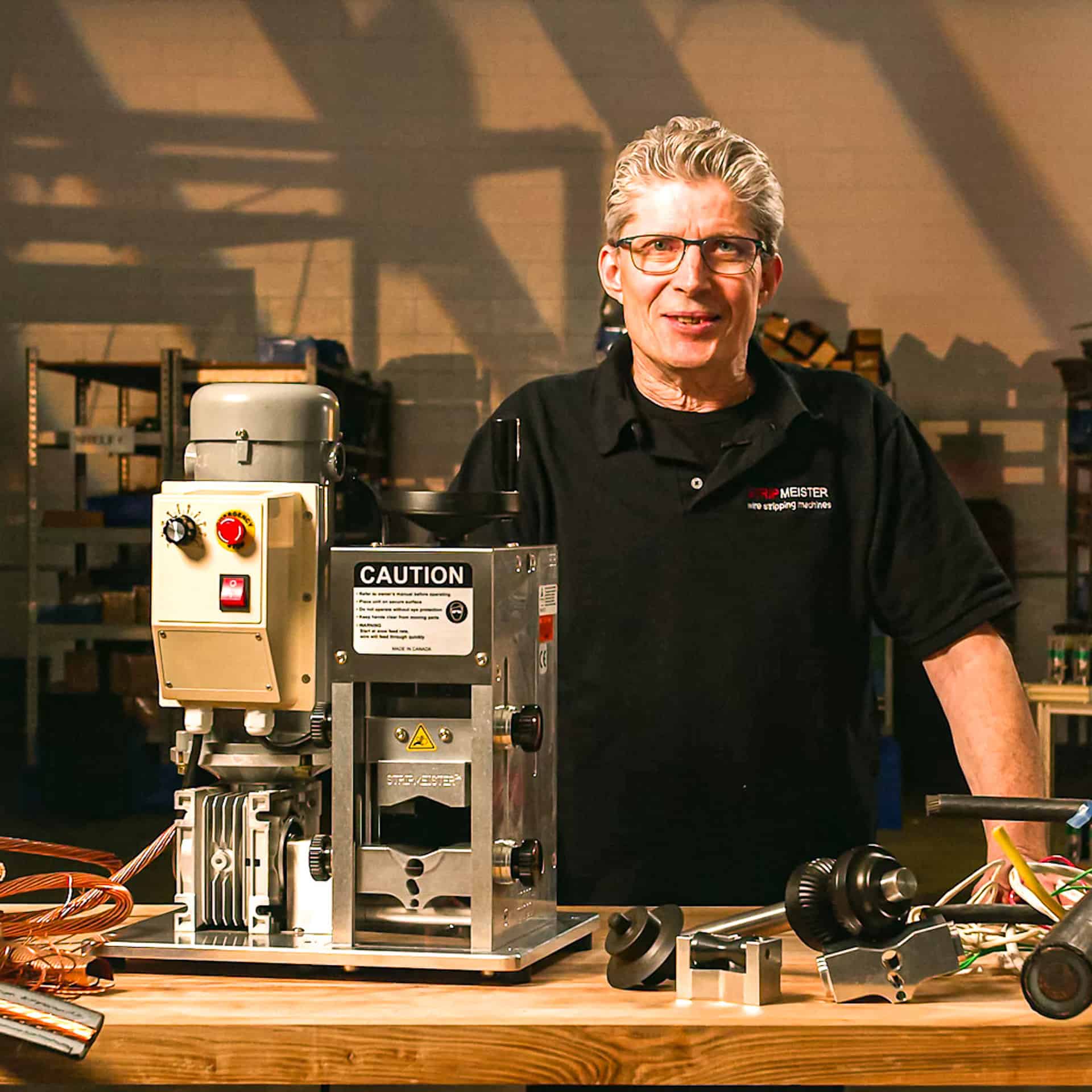

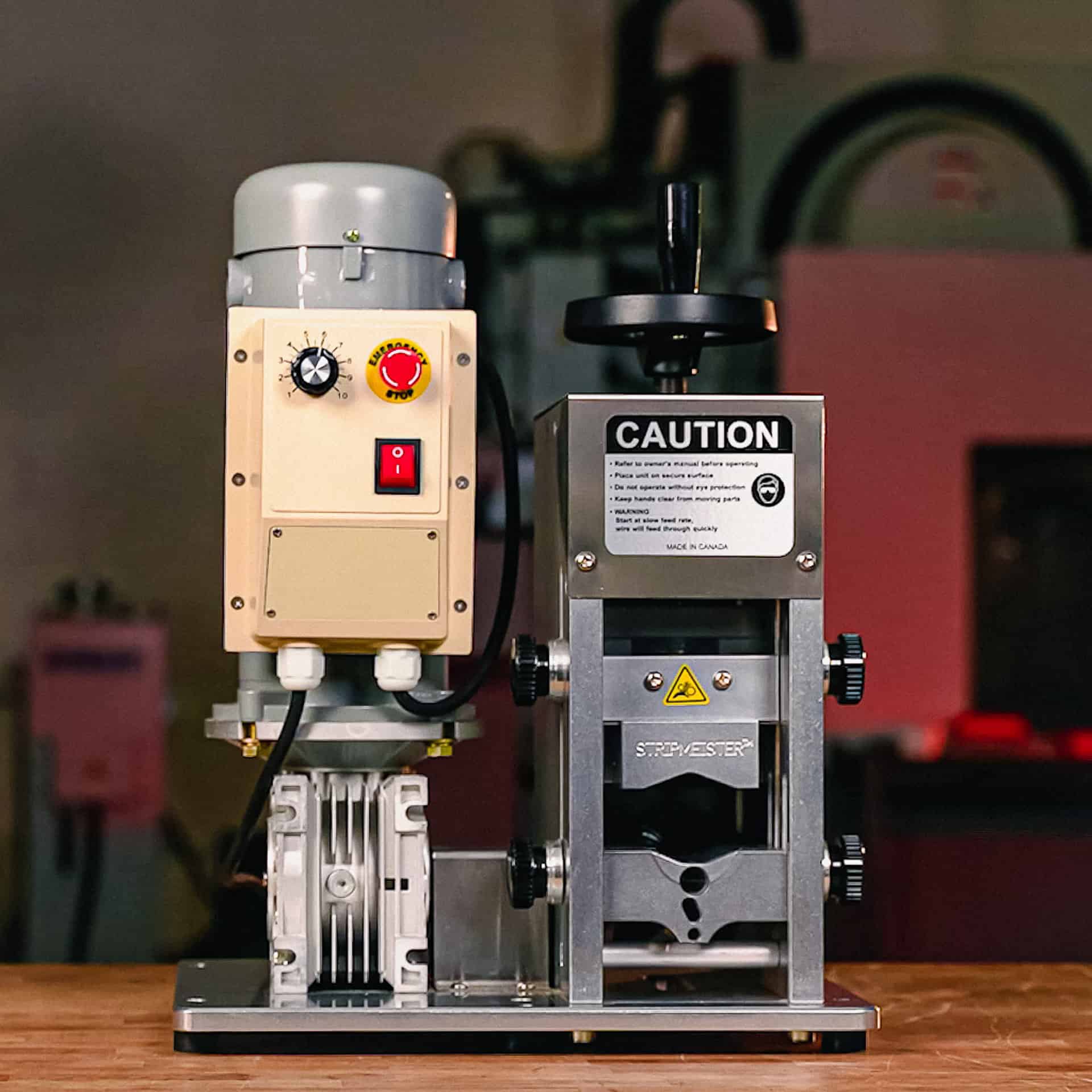

Drill Powered Wire Stripping Machine

Colby (verified owner) –

Best stripper I’ve ever had. She works like a charm!

Larry Doucet (verified owner) –

This is my 3rd one and its great the other 2 are going strong.

Matt Skinner (verified owner) –

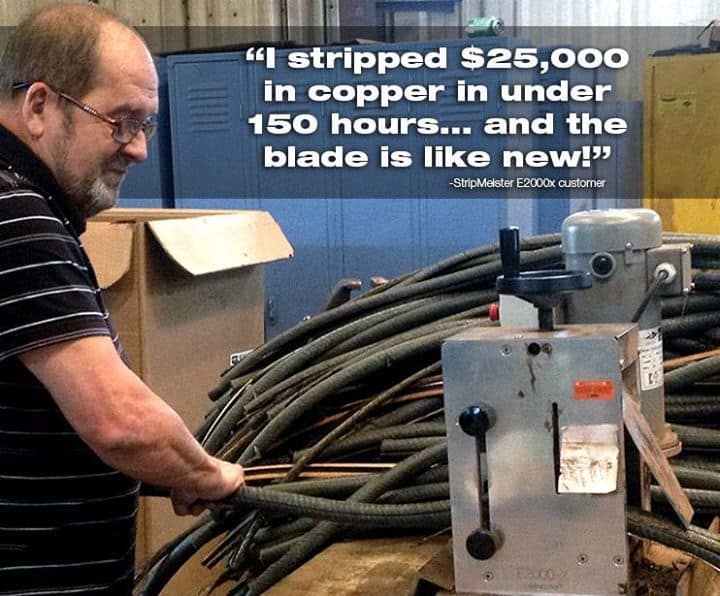

The StripMeister E2000X lives up to its name. It has handled thousands of feet of large cable without incident. Highly recommend it.

Roy Chisom (verified owner) –

Very nice machine