The StripMeister™ E1000

by Geoff Gariepy

What business do you advertise on the sign out front? How productive are you in performing that service or making that product?

Regardless of what it says on the sign, if you handle significant quantities of scrap insulated copper wire (ICW) in various sizes in the course of doing business, chances are you’re leaving money on the table.

The revenue your operation realizes from selling scrap ICW is important to your bottom line. Your profitability depends on earning as much as you can from the material you handle. Although you know you could sell your scrap ICW as #1 bare bright copper material for two to three times as much by stripping the insulation off, the amount of time required to strip it manually occupies either you or one of your employees in a low-productivity task that is not the main focus of your business. After all, you and your employees are far more productive and profitable when you stick to the type of work that’s advertised on the sign out front. And chances are, that sign doesn’t say anything about stripping wire!

Scrap Metal Prices Have Tanked

At the same time, the scrap metal market you came to depend on over the past few years to help your bottom line isn’t what it used to be.

You aren’t alone if you’ve noticed that prices have taken a dive. People in the industry are now talking like the lucrative scrap metal prices from just a few years ago were nothing more than a bubble that has since popped.

But your expenses sure haven’t taken a dive. You need that scrap metal’s revenue more than ever before. And with an uncertain economy, declining revenues in the scrap metal part of your business, labor costs continually rising, and ICW just as hard and time consuming to strip as ever, you know you need to make a big improvement in efficiency.

The Right Tool for The Job

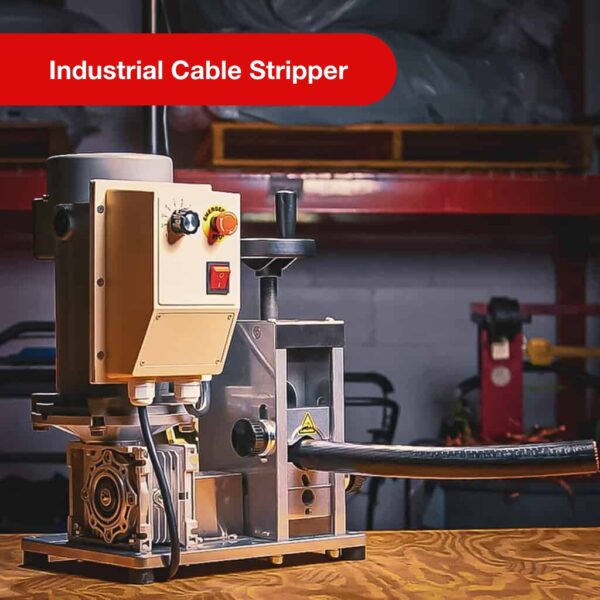

What if there was a way to get the insulation off the wire much more quickly and easily? What if there was a precision engineered, heavy duty tool that could handle stripping the serious volume of scrap ICW your business produces without breaking a sweat, or your bottom line? Wouldn’t you like to spend less time recovering value from your scrap ICW and more time concentrating on your main line of business? The StripMeisterTM E1000 automatic wire stripping machine can do all of this and more!

The folks behind the StripMeisterTM E1000 automatic wire stripping machine produce a well-engineered tool that is affordably priced at $1149. With an efficient, 1/2HP DC electric motor, featuring a Pulse Width Modulated speed control and a gear reduction drive, you get high torque and precisely adjustable cutting speeds. Cutting tool changes, which only come once every 8,000 pounds of wire, are a snap, and the machine realigns itself upon assembly, with no adjustments required. What’s more, the cutting tool is a precision CNC machined rotary knife made from hardened, heat treated tool steel, and is reasonably priced at $59.99, making the cost of consumables very affordable.

If you’ve been burned by poorly made equipment before, rest assured, they build the StripMeisterTM E1000 in an ISO-9000 certified factory right here in North America, and stand behind it with a full, yearlong warranty against manufacturer defects, so you know they’re confident in the quality of their equipment. This machine is a professional grade tool, built to last in a commercial or industrial environment for many years.

But How Quickly Does It Pay for Itself?

Let’s look at three of the common types of scrap ICW a business like yours typically handles, and see what kind of prices it brings when sold with the insulation still on and with insulation removed at a typical scrap yard in the United States. We’ll show how long it takes to remove the insulation manually, and compare this with how much more quickly it goes with the aid of a StripMeisterTM E1000 automatic stripping machine.

For the sake of discussion, let’s assume that the worker stripping the wire manually is the perfect, dream employee who has a perpetually sharp knife, never stops for coffee or smoke breaks, and is strong enough to strip hundreds of pounds of wire at a steady rate of 300 feet per hour unassisted. We’ll put his approximate labor cost to you, if you pay him $10 an hour, conservatively at $14.35/hour, benefits included. We’ll also show how long the same employee takes to strip the same wire using a StripMeisterTM E1000.

THHN/THHW 1/0 Copper Wire

| Original material | 100 feet of THHN/THHW 1/0 copper wire |

| Weight of wire with insulation still on the copper | 37.2 pounds |

| Scrap Yard classification | 80% wire, $.90/lb |

| ICW Selling Price | $33.48 |

| Copper Weight, Insulation Removed | 32.61 pounds |

| Manual time to strip | 20 minutes, at a labor cost of $4.78 |

| E1000 time to strip | 1.25 minutes, at a labor cost of $0.30 |

| Bare Bright Selling Price @ $2/lb | $65.22 |

| Employee productivity/hour, manual stripping

(300 feet stripped price – ICW price – labor) | $80.87 |

| Employee productivity/hour, E1000 stripping

(4800 feet stripped price – ICW price – labor) | $1,509.17 – 18+ times more productive! |

| E1000 ROI | 1,908 feet of this material, stripped in 23.86 minutes |

If your business handles scrap 1/0 Copper Wire in significant quantities, your E1000 could pay for itself roughly four times over before you would need to replace the blade for the first time! The E1000 is capable of processing this material at 80 feet per minute, which is roughly 16 times faster than our “perfect” employee can do it by hand and it will do so at a much lower overall cost.

That “E1000 ROI” figure listed above? That’s showing you that your StripMeisterTM E1000 could pay for itself in a little under twenty-four minutes (if you had enough of this material to keep it going for that long!)

But the real story here is how much more productive the worker operating the machine is than he is manually stripping wire. He adds $80.87 in value to the unstripped ICW in an hour, stripping 300 feet of it by hand. The same worker, operating the StripMeisterTM E1000, would add $1,509.17 in value to the 4800 feet of ICW he could strip bare in an hour. That’s an increase in his productivity of roughly 18 times!

250MCM Insulated Copper Wire

| Original material | 100 feet of 250MCM insulated copper wire |

| Weight of wire with insulation still on the copper | 85.1 pounds |

| Scrap Yard classification | Insulated Wire: $1.02/lb |

| ICW Selling Price | $86.80 |

| Copper Weight, Insulation Removed | 77.19 pounds |

| Manual time to strip | 20 minutes, at a labor cost of $4.78 |

| E1000 time to strip | 1.17 minutes, at a labor cost of $0.28 |

| Bare Bright Selling Price @ $2/lb | $154.38 |

| Employee productivity/hour, manual stripping

(300 feet stripped price – ICW price – labor) | $188.38 |

| Employee productivity/hour, E1000 stripping

(5100 feet stripped price – ICW price – labor) | $3,432.13 – 18+ times more productive! |

| E1000 ROI | 1,085 feet of this material, stripped in 12.76 minutes |

The StripMeisterTM E1000 really begins to shine when you’re feeding it 250MCM Insulated copper wire! Manufacturer rated to process this material at 85 feet per minute, it powers through our 100-foot sample of 250MCM in a little over one minute, ten seconds of operation, costing us a mere 28 cents worth of our worker’s time. How quickly could this machine pay for itself? Well, if you’ve got a significant quantity of scrap 250MCM, it will strip enough of it in thirteen minutes to cover its purchase price, labor costs included, even after deducting the value of the source material sold as ICW.

As for our worker’s productivity? Once again, he’s more than 18 times as productive operating the machine than he would be stripping that wire by hand.

1000MCM Insulated Copper Wire

| Original material | 100 feet of 1000MCM insulated copper wire |

| Weight of wire with insulation still on the copper | 326 pounds |

| Scrap Yard classification | Insulated Wire: $1.02/lb |

| ICW Selling Price | $332.52 |

| Copper Weight, Insulation Removed | 308.75 pounds |

| Manual time to strip | 20 minutes, at a labor cost of $4.78 |

| E1000 time to strip | 1.11 minutes, at a labor cost of $0.27 |

| Bare Bright Selling Price @ $2/lb | $617.15 |

| Employee productivity/hour, manual stripping (300 feet stripped price – ICW price – labor) | $840.59 |

| Employee productivity/hour, E1000 stripping (5400 feet stripped price – ICW price – labor) | $15,374.57 – 18+ times more productive! |

| E1000 ROI | 390 feet of this material, stripped in 4.33 minutes |

Would you have guessed that a StripMeisterTM E1000 could theoretically pay for itself in 2.24 minutes? If you’ve got a few hundred feet of scrap pieces of 1000 MCM in the back room, it can! After it’s done paying for itself, it will be ready to turn a profit for you for hundreds of more feet of wire before even needing a new cutting tool! Most importantly, however, the StripMeisterTM E1000 remains eighteen times more productive than a worker manually stripping wire in terms of dollars and cents.

Your $1149 investment is paying off huge dividends in profits and productivity!

Quick Change Artist

Of course, most businesses like yours don’t have a few thousand feet of the same type of scrap wire laying around waiting to be stripped. You more likely have a little bit of this, a little bit of that, and a pile or six of assorted other things, with a whole lot of it in short pieces! You might rip out a couple hundred feet of Romex one day, and salvage some heavy gauge scrap wire when you wire an industrial machine the next. If you’re a scrap yard, you’re getting all different kinds of wire every single day. Handling all of this efficiently by hand can be a nightmare, and the competition’s machines just aren’t up to the job.

Fortunately, the StripMeisterTM E1000 automatic wire stripping machine makes taming this jumbled assortment of wire types simple. It features a two-piece front wire guide that makes quick work of adjusting the machine to different sizes. It can handle everything from 18 gauge wire up to 1000 MCM, and it has the ability to precisely change the cutting speed to the rate that best suits the material. With a little bit of sorting, you can quickly set the machine up to process wire in batches, get through your scrap wire piles and turn them into profits quickly!

Most of our customers report back to us that their StripMeisterTM E1000 has paid for itself in a matter of a few hours of operation with the typical jumble of different wire sizes via its huge improvement in their productivity. After that, they tell us, the machine then goes on to earn profits for years after the initial investment has been recovered…profits that up until now the scrap copper wire part of your business just has not been able to generate.

Ready to Work, Everyday

It bears mentioning that the StripMeisterTM E1000 automatic wire stripping machine is not a cheap piece of junk made overseas. Designed and precision manufactured at an ISO-9001 certified factory right here in North America, the StripMeisterTM E1000 will handle your tough wire stripping jobs for years after it has paid for itself. It will do it in all kinds of weather, too: this machine is made of corrosion resistant aluminum and stainless steel, so if the wire stripping job needs to happen out in the back parking lot, a little rain or snow won’t hurt it. It even includes the StripMeisterTM-exclusive built-in Romex wire feed adapter, making the set-up for America’s most popular wire simple and easy.

Really, in these days of declining scrap metal prices and increasing costs, you can’t afford to do without one of these machines and the eighteen-fold increase in productivity it brings.

Additional Features

- Constructed of aircraft grade aluminum and stainless steel hardware, it will never rust

- Powerful, 1/2HP PWM variable speed controlled DC motor (runs on 60Hz 120V AC)

- Strips all sizes from #18 wire to 1000 MCM, Diameters from 0.11″ (2.7mm) up to 1.4″ (35.5mm) including ROMEX and braided (stranded) wire

- Blades last for about 8,000 pounds of wire apiece

- One-year warranty against manufacturer defects, and a 30-day, money back return policy

- Prompt shipping, and ready availability of replacement parts