For most electricians, using a wire stripper feels like second nature. Still, if you’re new to the StripMeister™ or just want to make sure you’re getting the best results, here’s a step-by-step guide to help you set up and operate your machine with confidence.

Step 1: Secure the Machine

Mount your StripMeister™ firmly to your workbench using the provided screws through the mounting holes. A solid base ensures smooth and safe operation.

Step 2: Attach Your Drill

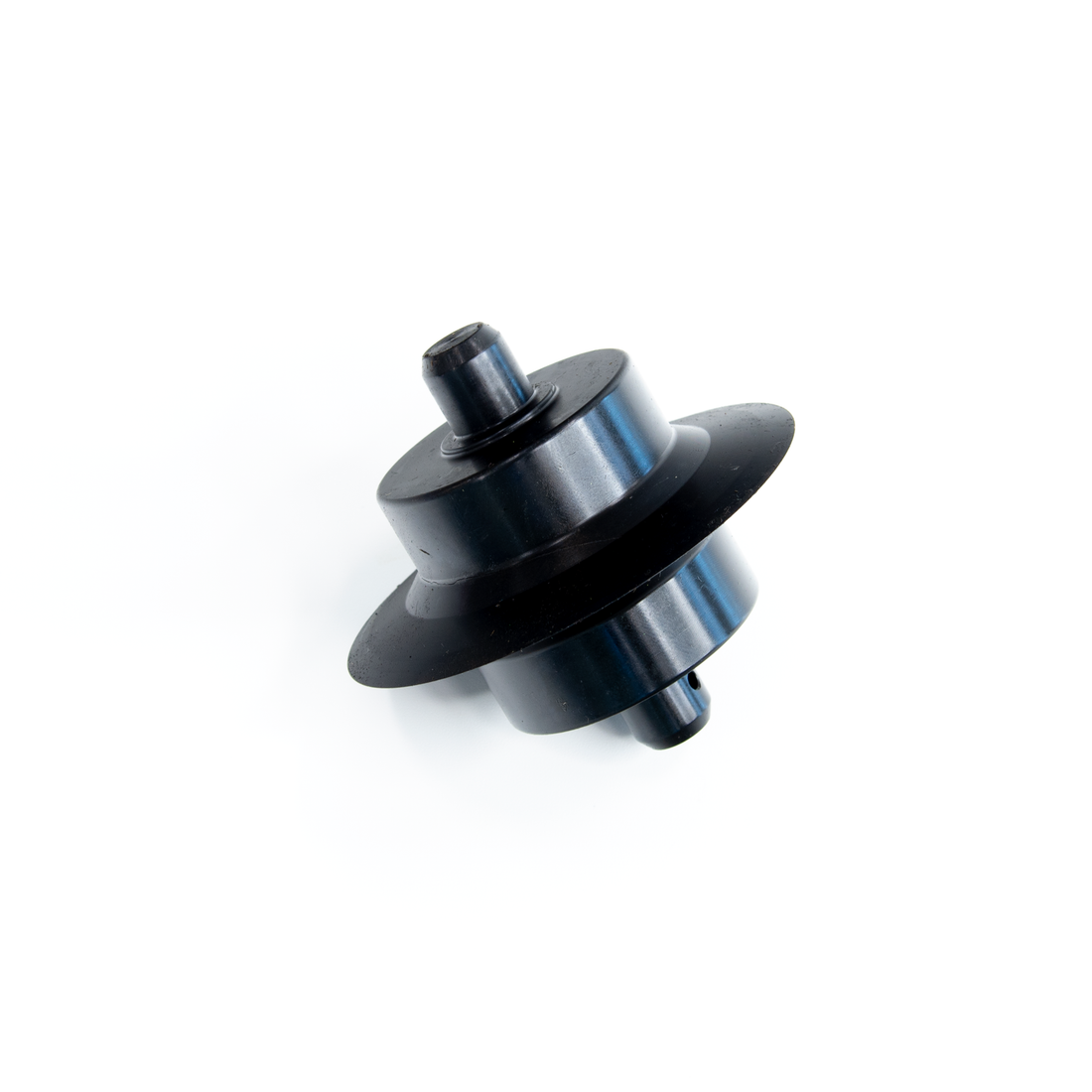

Connect a corded or cordless drill to the 5/16” feeder shaft and tighten it securely. This drill will power the wire feeder.

Step 3: Adjust the Wire Guide

-

Loosen the front wire guide so the wire can make contact with the feeder drive v-groove.

-

Feed the wire through the guide and into the v-groove.

Step 4: Set the Cutting Angle

-

Lower the knife blade until it just touches the wire’s insulation.

-

Position the front wire guide downward so the wire enters at a 10–20° angle.

-

Tighten the adjustment knob on the left side of the machine to lock the guide in place.

Step 5: Prepare the Knife Blade

-

Remove the wire.

-

Using the knife blade adjustment knob, lower the blade about 1¼ turns.

Step 6: Start Stripping

-

Start your drill.

-

Insert the wire into the feeder, and the machine will begin cutting automatically.

-

The wire will exit from the back of the StripMeister™ with a clean cut along the center.

Step 7: Peel the Insulation

Once cut, simply peel or strip the insulation off the wire.

Pro Tip

After your machine is set for a particular wire size, you can continue stripping wires of that size without making further adjustments. This makes bulk stripping faster and more efficient.